Energy

Environmentally sound technologies and high-tech materials

Energy requirements are increasing worldwide. The energy supply of the future requires among other things intelligent materials allowing a responsible handling during the generation, distribution and use of energy. Steels made by thyssenkrupp are an ideal material for the multifaceted energy industry meeting the high technical requirements on the material in terms of temperature, pressure and surface resistance.

With our high-quality product portfolio, we provide the right solution for regenerative and fossil energy generation, for the transportation and storage as well as the transformation of energy:

- non-grain-oriented electrical steel for generators

- grain oriented electrical steel for distribution transformers and power transformers

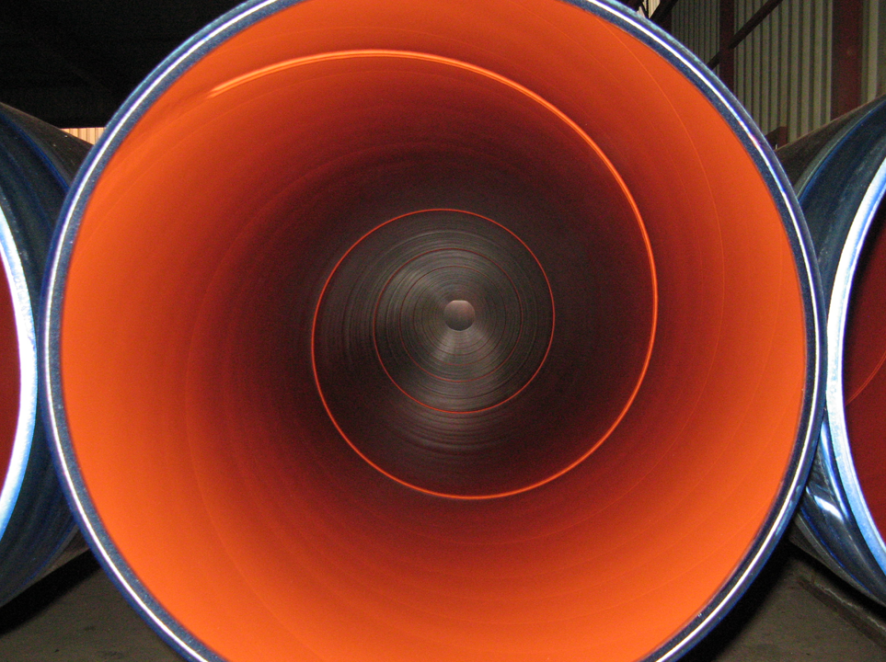

- tube & pipeline steels (hot strip, heavy plate)

- nickel steels for liquid-gas tanks

We continuously research and develop additional solutions supporting the increasing requirements of the energy industry. Among other things, we are working on an improvement with regard to the toughness and range of dimensions of line-pipes. With regard to other innovative products, R&D cooperations are a matter of course for us. Here, we attach great importance to long-standing partnerships.

Wind Power: powercore® Electrical Steel for Generators

Wind power giant Enercon based in the city of Aurich in Germany’s East Frisia region, numbers among the industry’s pioneers and innovators. The company owns over half of all patents worldwide for technologies associated with wind energy. Founded in 1984, Enercon has relied solely on gearless drive technology since 1992. Generators that form a single unit with the rotor hub optimize energy flow and ensure a long product life cycle. “Having fewer moving parts saves money and protects the environment,” says Matthias Dutsch, CEO of Induction, Enercon’s exclusive partner for generator production.

Partner for Wind Power Core Components

As a partner for the core components, the generators, Enercon has relied on powercore® products from thyssenkrupp Steel for many years. The electrical steel produced in Bochum is used throughout the entire energy supply chain of the electrical engineering process, from electricity production in the generators all the way to energy consumption in electric motors and other devices. These applications showcase powercore®’s excellent efficiency.

“The performance of the generators, and with it the efficiency of the entire wind farm, depends vitally on these special material properties,” explains Thomas Sube, Account Manager for Non-Oriented Electrical Steel Application Technology, thyssenkrupp Steel. The properties of the electrical steel were specially optimized for use at Enercon and produced from a custom alloy to ensure higher conductivity and stamping suitability. This is yet another reason for the rise in wind farm efficiency over the past few years.

Steel Recycling in the Wind Energy Sector

Enercon bucks current market trends, choosing instead to consolidate its important manufacturing processes internally. The company even operates its own foundry, where it produces rotor hubs, machine mounts, and blade adapters. Each component weighs several tons. What is notable here is that almost half of the materials used are steel scrap sourced from the company’s own generator factory. The scrap from electrical steel stamping is collected, smelted, and recycled. The process was made possible through close cooperation between Enercon and its loyal partner in Bochum. The companies worked together to optimize the mix of materials used to produce the electrical steel.

Worldwide Expansion of Wind Power

Excellence pays off: The international wind market has its sights set on Aurich. Wind turbines manufactured in East Frisia now operate on a bluff in Brittany, on the gentle slopes of Anatolia, and in the northern Swedish province of North Bothnia. Following a successful testing phase in the Netherlands, the latest generation, E-138 EP3, will now be making its way overseas. One hundred twenty EP3 wind turbines are travelling to Canada by ship.