precidur® HSM 700 HD

perform® 550 HD

CP-K® 780Y980T2

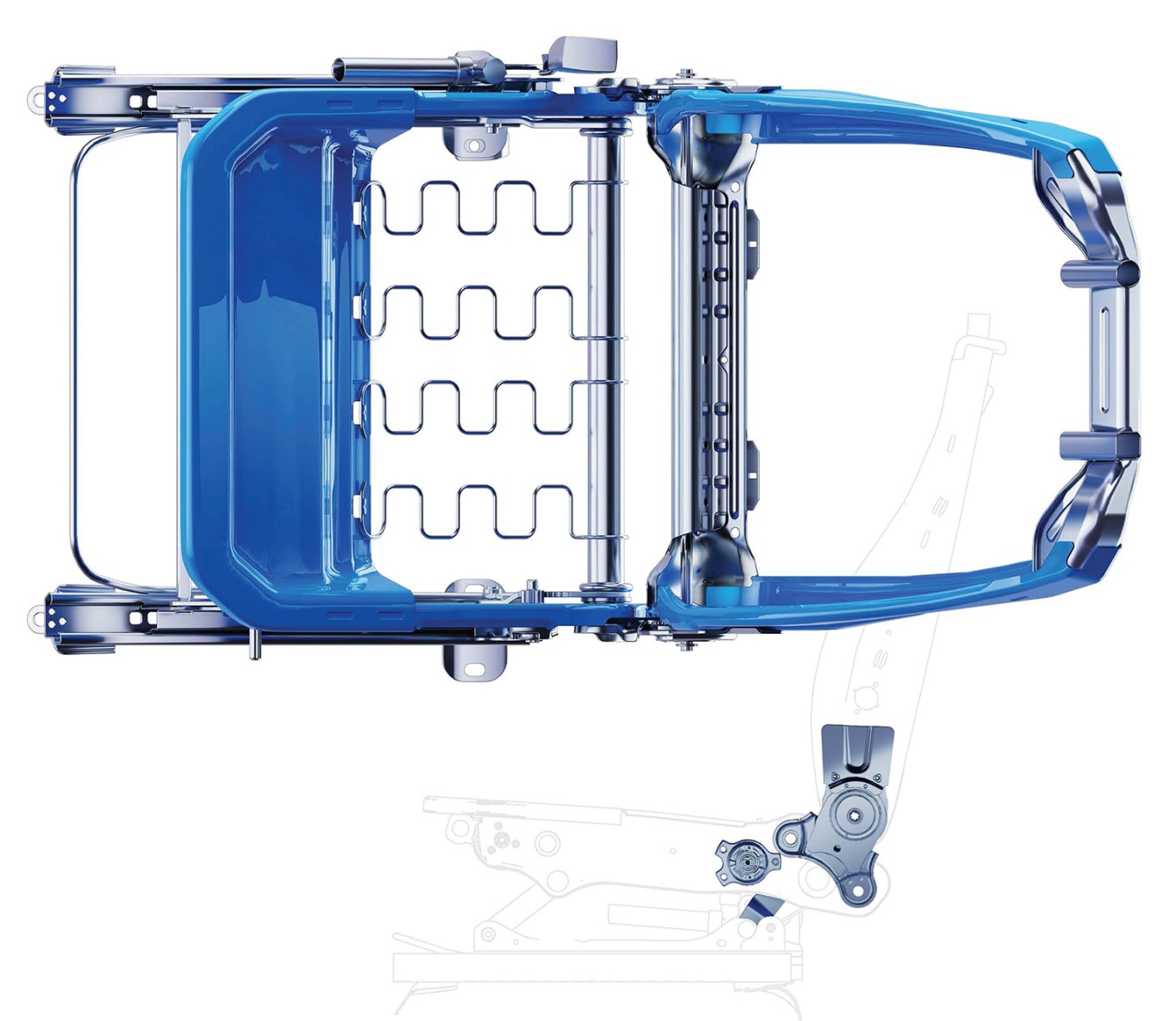

Modern car seat has to be a true all-rounder: it has to be lightweight yet crash-proof, take up very little installation space, be inexpensive to produce – and all of this, of course, without compromising comfort. The use of high-strength steel helps to meet these diverse requirements.

Take the issue of weight, for example: Today, each seat weighs on average around 12.5 kilograms – and that’s just the load-bearing steel seat structures. Together, then, the front and rear seat structures of a car can easily weigh in at around 50 kilos. A tailored portfolio of steel grades to meet to the specific seating requirements have a noticeable positive impact here and help reduce weight by up to 15 percent – at no extra cost.

precidur® HSM 700 HD

perform® 550 HD

CP-K® 780Y980T2

perform® 355

DP-K® 440Y780T HHE

CP-K® 570Y780T

MHZ® 340

MHZ® 380

DP-K® 290Y490T

perform® 500 HD

CP-W® 660Y760T

DP-K® 700Y980T

MHZ® 420

DP-K® 440Y780T HHE

MHZ® 420

DP-K® 440Y780T HHE

DP-K® 590Y980T

DP-K® 700Y980T

precidur® HLB 22

precidur® HSM 700 HD

precidur® HSM 650 HD

scalur® S600MC

precidur® HLB 37

precidur® HSM 700 HD

Seat structures are a complex system in which every single structural component is important. Take safety: The front seatback is stressed by the passenger in the event of a rear-end crash and by whatever’s on the rear seat or possibly in the trunk in a frontal collision. Accordingly, different crash load cases must be considered for the backrest side member, cushion side member, and seat shell.

A task made for our robust high strength dual-phase steel DP-K® 440Y780T HHE. With a rating of 800 MPa, this cold-rolled dual-phase steel is not only extremely strong but also easy to form, making it perfect for difficult-to-form structural components that are exposed in the event of a crash, such as the backrest side member.

Material recommendation:

Depending on the shape of the component in question, dual-phase steel DP-K® 700Y980T or highly ductile micro-alloyed steel perform® 500 HD can be used, e.g., for the cushion side member (the new HD steel grade is particularly easy to form).

Material recommendation:

Highly ductile micro-alloyed, high-strength perform® steels (hot wide strip) as well as precidur® steel grades made from Hohenlimburg precision steel in particular are ideal for classic cold-rolling processes and seat rail applications. Finally, the cold-rolled uncoated complex-phase steel CP-K® 780Y980T is another high-performance material in the 1,000 MPa strength class that features excellent forming properties and meets the highest thickness tolerance requirements – and not only for seat rails.

Material recommendation:

The case-hardening and tempered steels and the highly ductile micro-alloyed fine-grain structural steels of the precidur® family, for example, offer hot-rolled precision strip with extremely tight thickness and profile tolerances that is ideally suited to making functional components such as adapter units, seat height adjusters and articulated levers.

Material recommendation adapter unit:

Material recommendation seat height adjuster:

Material recommendation articulated lever:

DP-K® 290Y490T (tolerances ±0.05 mm, tighter tolerances on request)

MHZ® 420, standard thickness approx. 0.6 mm

HC460LA, standard thickness approx. 0.5 mm

scalur® S420MC

DP-K® 700Y980T, ideal for roll forming

CP-K® 570Y780T

DP-K® 440Y780T

HC460LA

While seat structures for front seats have the same or comparable structure depending on the car model, rear seat structures vary greatly depending on the vehicle, e.g. adjustable individual seats, divisible or non-divisible rear seat benches with profiles or tubes.

Micro-alloyed steels HC420LA and HC460LA are predestined for forming operations such as flanging and beading and therefore ideally suited for the production of rear seat panels. Profiles and reinforcement brackets are used to meet the high crash requirements of the rear bench seat (e.g. load case: protection against load). Our steel grade scalur® S420MC, pickled micro-alloyed hot-rolled strip with extremely narrow thickness tolerances of up to ±0.05 mm and a very flat profile, offers not only the best processing properties but also high lightweighting potential.

Material recommendation rear seat panels:

Material recommendation reinforcement brackets:

Dual-phase steel DP-K® 700Y980T (ideally suited for roll forming) and complex-phase steel CP-K® 570Y780T are both suitable for rear seat structures in tubular design. Both steel grades combine high strength with good formability and offer high lightweighting potential.

Material recommendation:

| Steel grade |

Reference grade DIN EN 10152 |

Reference grade VDA 239-100 |

|---|---|---|

| DP-K® 290Y490T |

HCT490X | CR290Y490T-DP |

| DP-K® 330Y590T |

HCT590X | CR330Y590T-DP |

| DP-K® 440Y780T HHE1 | HCT780X | CR440Y780T-DP2 |

| DP-K® 590Y980T | HCT980X | CR590Y980T-DP |

| DP-K® 700Y980T | HCT980XG | CR700Y980T-DP |

| DP-K® 900Y1180T | – | – |

| Steel grade |

Reference grade DIN EN 10338, 10346 |

Reference grade VDA 239-100 |

|---|---|---|

| CP-W®660Y760T | HDT760C | HR660Y760T-CP |

| CP-K® 570Y780T | HCT780C | CR570Y780T-CP |

| CP-K® 780Y980T | HCT980C | CR780Y980T-CP |

| CP-K® 900Y1180T | – | CR900Y1180T-CP |

| Steel grade DIN EN 10346 |

Steel grade VDA 239-100 |

Thickness1 from _ to in mm |

Width1 from _ to in mm |

|---|---|---|---|

| HX340LAD | HR340LA | 1.50 – 4.00 | 900 – 1,550 |

| HX380LAD | HR380LA | 1.50 – 4.00 | 900 – 1,550 |

| HX420LAD | HR420LA | 1.50 – 4.00 | 900 – 1,550 |

| HX460LAD | HR460LA | 1.80 – 3.00 | 900 – 1,500 |

| Steel grade |

Reference grade DIN EN 10149-2 |

Reference grade VDA 239-100 |

Material no. |

Thickness1 from _ to in mm |

Width1 from _ to in mm |

|---|---|---|---|---|---|

| perform® 315 HD | S315MC | – | 1.0972 | 1.50 – 6.00 | 50 – 1,600 |

| perform® 340 HD | S340MC | HR340LA | – | 1.50 – 6.00 | 50 – 1,600 |

| perform® 355 HD | S355MC | – | 1.0976 | 1.50 – 6.00 | 50 – 1,600 |

| perform® 420 HD | S420MC | HR420LA | 1.0980 | 1.50 – 6.00 | 50 – 1,600 |

| perform® 460 HD | S460MC | HR460LA | 1.0982 | 1.80 – 6.00 | 50 – 1,600 |

| perform® 500 HD2 | S500MC | HR500LA | 1.0984 | 1.50 – 5.49 | 50 – 1.600 |

| perform® 550 HD | S550MC | HR550LA | 1.0986 | 1.50 – 6.00 | 50 – 1,600 |

| Steel grade |

Reference grade DIN EN 10149-2 |

Reference grade VDA 239-100 |

Material no. |

THICKNESS1 from _ to in mm |

WIDTH1 from _ to in mm |

|---|---|---|---|---|---|

| perform® 210 | – | HR210LA | – | 2.00 – 12.50 | 50 – 2,000 |

| perform® 240 | – | HR240LA | – | 2.00 – 12.50 | 50 – 2,000 |

| perform® 270 | – | HR270LA | – | 2.00 – 12.50 | 50 – 2,000 |

| perform® 300 | – | HR300LA | – | 2.00 – 12.50 | 50 – 2,000 |

| perform® 315 | S315MC | – | 1.0972 | 1.50 – 12.50 | 50 – 2,000 |

| perform® 340 | – | HR340LA | – | 1.50 – 19.00 | 50 – 2,000 |

| perform® 355 | S355MC | – | 1.0976 | 1.50 – 19.00 | 50 – 2,000 |

| perform® 380 | – | HR380LA | 1.0978 | 1.50 – 19.00 | 50 – 2,000 |

| perform® 420 | S420MC | HR420LA | 1.0980 | 1.50 – 19.00 | 50 – 2,000 |

| perform® 460 | S460MC | HR460LA | 1.0982 | 1.80 – 19.00 | 50 – 2,000 |

| perform® 500 | S500MC | HR500LA | 1.0984 | 1.50 – 19.00 | 50 – 2,000 |

| perform® 550 | S550MC | HR550LA | 1.0986 | 1.50 – 8.50 | 60 – 2,000 |

| perform® 600 | S600MC | HR600LA | 1.8969 | 2.00 – 9.50 | 80 – 1,800 |

| perform® 650 | S650MC | HR650LA | 1.8976 | 2.00 – 12.00 | 80 – 1,600 |

| perform® 700 | S700MC | HR700LA | 1.8974 | 2.00 – 12.00 | 80 – 1,800 |

| Steel grade |

Standard designation DIN EN 10149-2 |

Standard designation VDA 239-100 |

Material no. |

Thickness1 from _ to in mm |

Width1 max. in mm |

|---|---|---|---|---|---|

| precidur® HSM 650 HD | S650MC | - | 1.8976 | 1.50 – 16.00 | 720 |

| precidur® HSM 700 HD | S700MC | HR700LA | 1.8974 | 1.50 – 16.00 | 720 |

| Steel grade |

Standard designation DIN EN 10083 |

Material no. |

Thickness1 from _ to in mm |

Width1 max. in mm |

|---|---|---|---|---|

| precidur® HLB 22 | 22MnB5 | 1.5528 | 1.50 – 16.00 | 720 |

| precidur® HLB 37 | 37MnB4 | 1.5524 | 1.50 – 16.00 | 720 |

Automotive supplier Brose has teamed up with thyssenkrupp Steel to investigate the forming behavior of high-strength complex-phase steels during collar drawing. The aim was to optimize the process using a numerical simulation - based on a new material card.

When it comes to further developing processes in the automotive industry, practical cooperation is required. Such as between thyssenkrupp Steel and automotive supplier Brose.

In collar drawing, a hole is punched into a steel blank, the edge of which is then raised to form a flange. This raised zone – the so-called collar – serves as a functional connecting element in the subsequent component and thus, for example, as a bearing point or preliminary stage for thread forming. The particular challenge is that the cut edge of the material is subjected to high stresses. Depending on the degree of deformation and the interaction with the materials used, different boundary conditions arise until the material reaches the load limit. The exact prediction of this behavior is crucial for the process design – especially for high-strength materials.

The project focused on the cold-rolled complex-phase steel CP-K® 780Y980T from thyssenkrupp Steel. With a tensile strength of at least 1,000 megapascals and its fine-grained microstructure, it combines high strength, good hole expansion and reliable formability – all properties that predestine it for crash and safety-relevant applications in lightweight automotive construction. "Our customers are increasingly demanding reliable data for new materials - not only on mechanical properties, but also on overall process behavior," explains Sarah Abraham, Product Manager at thyssenkrupp Steel. The behavior is particularly complex at the cutting edge, as it is strongly influenced by the microstructure and the forming process."

"CP-K® grades allow us to rethink geometric freedoms, for example at bearing points. Although these can still be implemented afterwards, this involves additional work steps," says Gerald Erdmann from Brose's Materials Development and Sustainability department. “Our CP-K® 780Y980T is characterized not only by its excellent local but also by a comparatively high global forming behavior,” adds Sarah Abraham.

In order to provide valid information, thyssenkrupp Steel conducted extensive tests to create a validated material card for its high-strength, cold-rolled CP-K® 780Y980T, which also takes fracture mechanical parameters and cutting edge properties into account. "With our testing equipment, we are able to create material cards that can be used for both forming and crash applications. The focus here is on our customers' requirements, which can be requested from us at any time on a customer-specific basis," explains Hartwig Rösen, from the materials modeling department at thyssenkrupp Steel. At the same time, practical collar pulling tests were carried out in the Dortmund technical center of the steel manufacturer Dortmund in order to demonstrate real load and failure mechanisms on the material.

In the next step, Brose took over the numerical modeling: detailed simulations of the collar pulling process were created using the data provided by thyssenkrupp Steel. The focus was particularly on sensitivity analyses, i.e. the question of how strongly changes in friction, cutting force or edge radius affect the result. “The data provided gave us a very good foundation for the digital mapping of the process,” says Alexander Kulikov, Project Engineer Simulation at Brose. “This not only allowed us to systematically compare variants, but also to supplement the physical tests in a targeted manner.” The results show: The real and simulative observations match – particularly with regard to the geometry of the formed collars and the influence of cut edge quality. There are still slight deviations with regard to the exact fracture behavior, which can now be used to further refine the models.

“Our detailed material cards are key to the digitalization of forming processes,” emphasizes Sarah Abraham. “They enable realistic simulations – and therefore save valuable time and resources.” From thyssenkrupp Steel's perspective, the project is a successful example of a successful development partnership. “When materials knowledge, application technology and customer requirements come together, resilient solutions for real challenges are created,” says Stefan Woestmann, application engineer at thyssenkrupp Steel. “This is not only helpful in specific cases – it also provides a valuable basis for future developments.”

“The collaboration with thyssenkrupp Steel enables us to incorporate our experience into both the design of the stamping processes and the subsequent forming,” says Thomas Kreissl, forming technology technologist at Brose, summing up the successful project.

With two new high-strength, cold-rolled multiphase steels with special forming properties, thyssenkrupp Steel is supplying the automotive industry with ideal materials for weight-reduced seat structures.