The essential raw material, iron ore in the form of pellets, for the direct reduction process is stored in the direct reduction plant's pellet and raw material store. The store is designed to provide a continuous supply to the plant to ensure seamless running of the direct reduction process.

Sustainably

entering a new era of steel production

We are making industrial history once again at thyssenkrupp Steel with our transformation into a carbon-neutral steel producer. Everyone stands to benefit from the success of one of the biggest industrial decarbonization projects worldwide – the construction of our new direct reduction plant, which is scheduled to come on stream at 2027.Our steel: the starting point for the industrial value chain of the future, the success of the turnaround in energy and climate policy, with long-term job prospects in Germany and throughout Europe.

Blueprint for decarbonization of industry. Engine of the European hydrogen economy. An important decision for climate change mitigation and for Germany as an industrial center.

The 100% hydrogen-capable direct reduction plant with two melters has a production capacity of 2.5 million metric tons of directly reduced iron per year. It is the first plant combination of its kind in the world with this technological concept. This will make thyssenkrupp Steel a pioneer in the decarbonization of the steel value chain in Europe and, among other things, guarantee indispensable specialty materials for the success of the energy and mobility revolution.

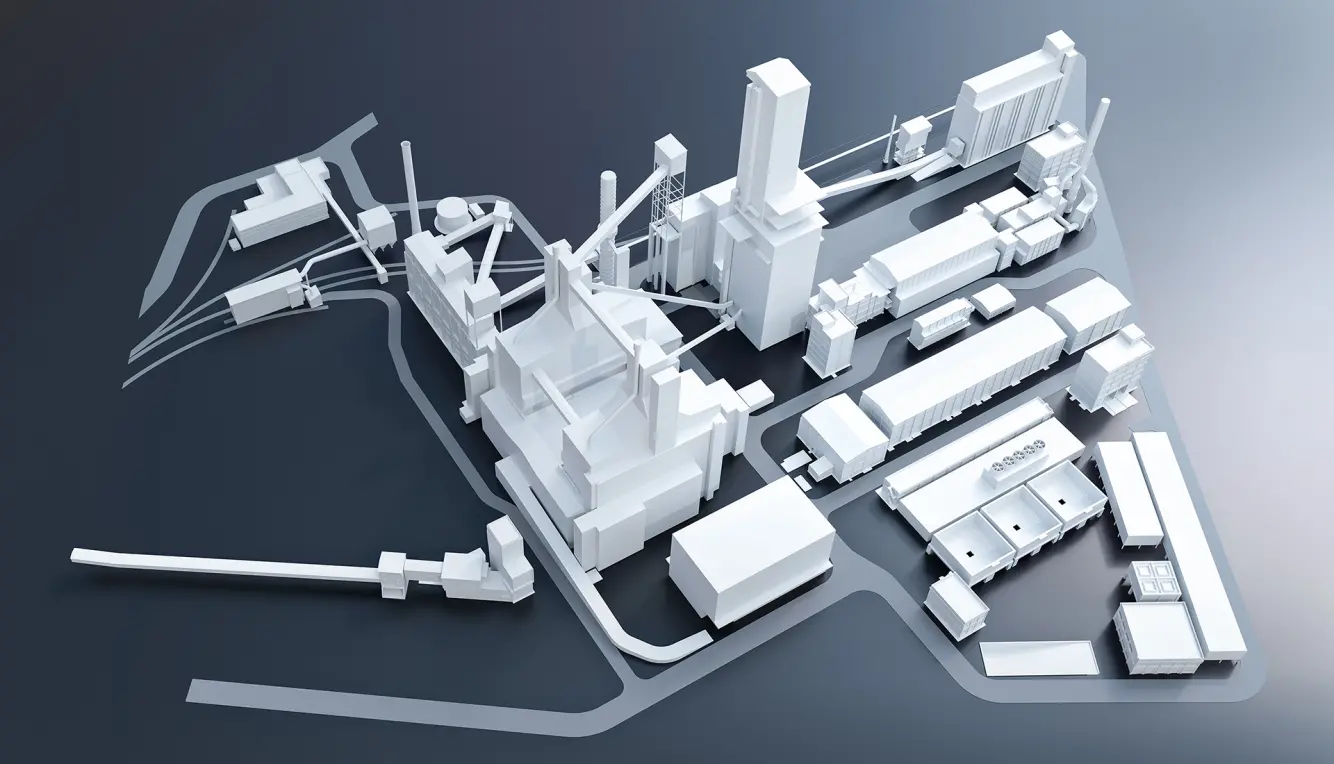

Demonstration model DR plant

An important step for the transformation of the steel industry: construction of the first hydrogen-based direct reduction plant at the Duisburg site with a capacity of 2.5 million metric tons of directly reduced iron (DRI), and an annual saving of up to 3.5 million metric tons of CO2.

Construction of the plant on an EPC basis (Engineering, Procurement and Construction) by the SMS group.

The direct reduction tower is the central unit of a reduced-CO2 steel production plant that replaces the conventional blast furnace processes. This tower is where the direct reduction of iron from iron ore takes place with the help of reduction gases such as hydrogen (H2). The result is solid, spheroidal iron that is liquefied in the melters before further processing in the steel mill.

The process gas required for the reduction is generated in the reformer.

The reduction gas is reformed at high temperatures from a variable mixture of hydrogen, natural gas and process gases.

The melter, also known as Submerged Arc Furnace (SAF), is characterized by its use of a melting process in which the metal is melted openly in a bath, as opposed to closed melting furnaces such as the Electric Arc Furnace (EAF). The SAF enables efficient melting and thus plays an important role in metallurgy. In addition, the slag produced in the melting process can be further processed into granulated blast furnace sand, and used as a valuable raw material in the cement industry.

The casting hall is the area where the molten hot metal from the melter is poured into what are called transport ladles, which in turn are transported to the actual BOF meltshop for further processing.

Slag granulation is a process used in the steel industry to process the slag generated during steelmaking. In the process, the hot molten slag is quickly cooled and granulated. The blast furnace slag produced in this way can be used as a valuable raw material in the cement industry.

Sustainable steel production

that saves up to 3.5 million metric tons of CO2 in the first step alone.

Away from iron ore reduction by carbon in the blast furnace. Towards hot metal production through the use of hydrogen in the direct reduction plant and with the help of newly developed melters in the direct reduction plant. A gigantic conversion job which will save up 3.5 million metric tons of CO2 in steel production in the first stage alone. This corresponds to about 2% of the emissions in North Rhine-Westphalia.

But this is just the beginning. By 2045 at the latest, we will be producing carbon-neutral steel at the Duisburg site. To put it in context: With the conventional steelmaking process in our blast furnaces, we are responsible for 20 million metric tons of CO2 per year, and thus for around 2.5% of Germany's CO2 burden. With the new plant, we are already replacing one blast furnace.

Sustainable steel

for Germany's independence and economic might.

Steel is an indispensable basic material for the energy and mobility revolution. And in perspective, in green as well.

Being Germany's biggest producer of flat steel entails an immensely significant role in the future of the domestic economy. After all, thyssenkrupp Steel's successful transformation will make a major contribution toward helping entire sectors of the economy achieve their climate targets. Sustainable steel with a low carbon footprint is the material that is needed now to enable value creation to continue in Germany.

Sustainable steel

that will accelerate the development of the hydrogen economy.

The need for carbon-neutral hydrogen is just as huge as the task of converting our hot metal production. The direct reduction plant will require more hydrogen every two hours than will fit in the Oberhausen gasometer, for example.

Being able to sell such unimaginably large quantities of hydrogen means that European hydrogen manufacturers can now invest massively with great planning certainty. As one of the very important customers in the future, we are thus accelerating the ramp-up of the hydrogen economy.

Sustainable steel

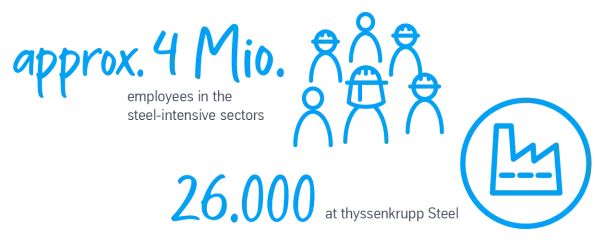

that secures jobs and prosperity.

We are strengthening our industrial base and securing attractive jobs in the region – 26,000 directly in the company, 150,000 in downstream industries in North Rhine-Westphalia, while nationwide there are as many as four million jobs in steel-intensive sectors. Our transformation will lead to a large number of new career profiles, make for a qualification boost and create jobs with a secure future.

To put it briefly: we will not only maintain the quality standards of our steel grades. Employees in our plants, at suppliers and processors also stand to benefit from this – both in the Ruhr region and beyond. This means our steel is the starting point for the industrial value chain of the future, the success of the turnaround in energy and climate policy, and for lots of high-quality jobs in Germany and throughout Europe.

Contact

Mark Stagge

Head of Public & Media Relations, thyssenkrupp Steel Europe

Roswitha Becker

Press spokesperson, thyssenkrupp Steel Europe