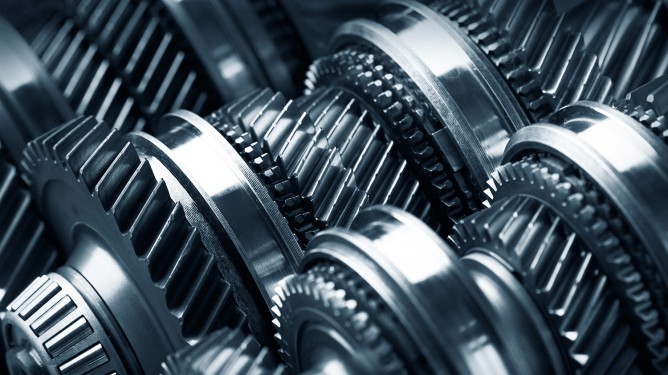

Typical applications of case-hardening steel

Case-hardening steel is used in automotive engineering as well as in mechanical and plant engineering for parts such as cardan shafts, coupling parts, gears and bolts.

thyssenkrupp supplies the following steel grades as per the product information or the reference steel grades in accordance with the respective standards.

Case-hardening steel according to DIN EN ISO 683-3 (previously DIN EN 10084), DIN EN 10132-2

| Steel grade designation | Reference grade | Material no. | THICKNESS1 from _ to in mm |

WIDTH1 from _ to in mm |

|---|---|---|---|---|

| C10 | C10 | 1.1121 | 1.91 – 20.00 | 50 – 1,630 |

| C15 | C15 | 1.1141 | 1.91 – 20.00 | 50 – 1,630 |

| 16MnCr5 | 16MnCr5 | 1.7131 | 2.00 – 13.00 | 50 – 1,630 |

| 20MnCr5 | 20MnCr5 | 1.7147 | 2.00 – 13.00 | 50 – 1,630 |

Chemical composition

| Steel grade | C [%] | Si [%] max. |

Mn [%] | P [%] max. |

S [%] max. |

Cr [%] max. / - |

|---|---|---|---|---|---|---|

| C10 | 0.07 – 0.13 | 0.40 | 0.30 – 0.60 | 0.025 | 0.010 | 0.30 |

| C15 | 0.12 – 0.18 | 0.40 | 0.30 – 0.60 | 0.025 | 0.010 | 0.30 |

| 16MnCr5 | 0.14 – 0.19 | 0.40 | 1.00 – 1.30 | 0.025 | 0.010 | 0.80 – 1.10 |

| 20MnCr5 | 0.17 – 0.22 | 0.40 | 1.10 – 1.40 | 0.025 | 0.010 | 1.00 – 1.30 |