Strip shape

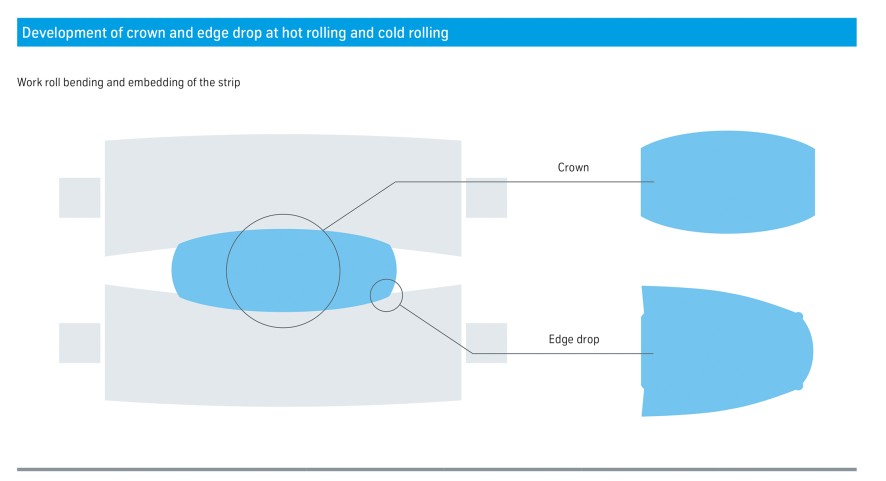

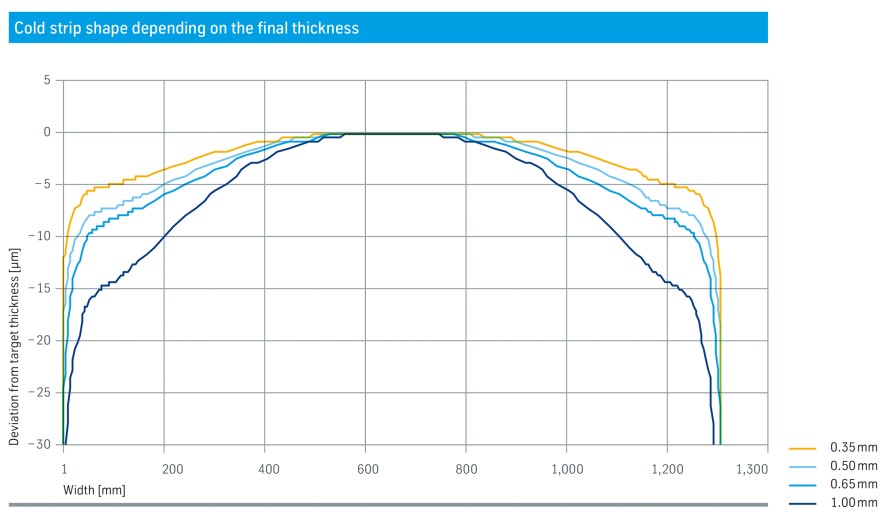

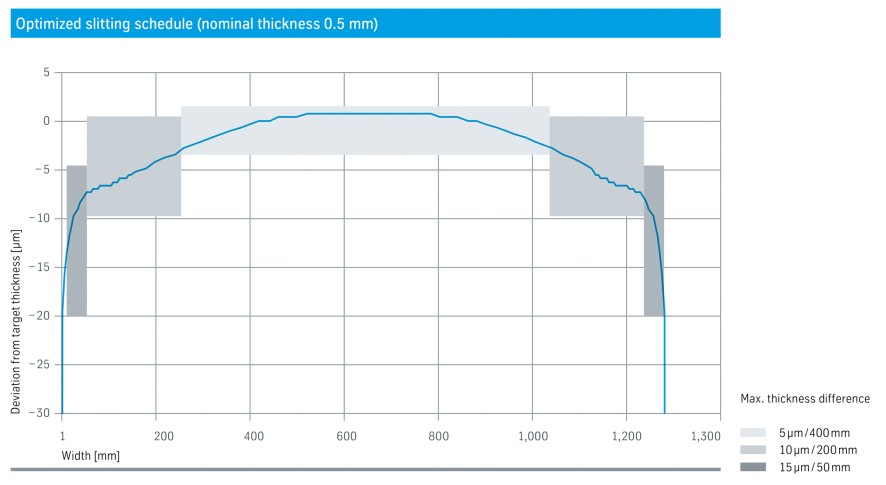

Thanks to continuous improvements to manufacturing processes, all powercore® grades display a very flat strip shape. However, owing to physical conditions during rolling, thickness variations over strip width can only be reduced to a limited extent.

Thickness deviations1

| Thickness deviations | Unit | NOMINAL THICKNESS inm mm | |||

|---|---|---|---|---|---|

| 0,35 | 0,50 | 0,65 | 1,00 | ||

| Max. deviation from nominal thickness | % | ±8 | ±6 | ±5 | ±5 |

| Max. thickness variation parallel to rolling direction within one sheet or strip with a length of 1 m | % | 6 | 4 | 4 | 4 |

| Max. variation of thickness transverse to rolling direction at a minimum distance of 30 mm from the edge | mm | 0,02 | 0,02 | 0,03 | 0,03 |

1 Electrical steel for e-mobility and high frequencies according to DIN EN 10303.