Steels and coatings for hot forming:

MBW® and AS Pro

For hot forming thyssenkrupp supplies hot-rolled, cold-rolled and coated MBW® manganese-boron steels. A newcomer to the range: AS Pro, the innovative coating for significantly improved component and process reliability in automotive engineering.

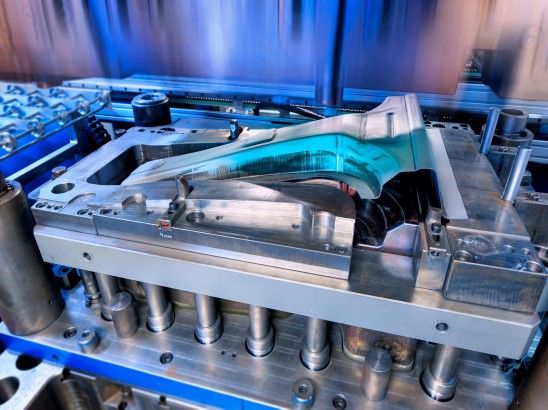

In the automotive industry MBW® manganese-boron steels are mainly used for safety-relevant structural parts, including A- and B-pillars, bumper crossbeams, side impact beams and body reinforcements. Our MBW® steels offer extremely high strengths after hot forming while retaining very good forming properties.

Our materials and automotive expertise for hot forming

- Materials: Our portfolio of hot forming steels includes hot-rolled, cold-rolled and coated MBW® manganese-boron steels.

- Process: Established and patented tailored tempering process for hot forming that makes it possible to integrate different, precisely controlled elongation and strength properties into different areas of the same monolithic part.

The right property in the right place – tailored properties for hot-formed components

Depending on the demands placed on the components, tailored production processes like Tailored Welded Blanks, partial press hardening – be it Tailored Tempering in the die or in the hot forming furnace, flexible rolling or the use of patched blanks – comprise technical solutions for which thyssenkrupp Steel offers a wide range of uncoated and AS-coated MBW® steels for hot forming. All these solutions show weight saving potential for crash-relevant structural car parts with additional local optimization of properties. A Tailored Welded Blank, can, for instance, also be a tailored overall solution for a hot-formed door ring.