powercore® PP grades

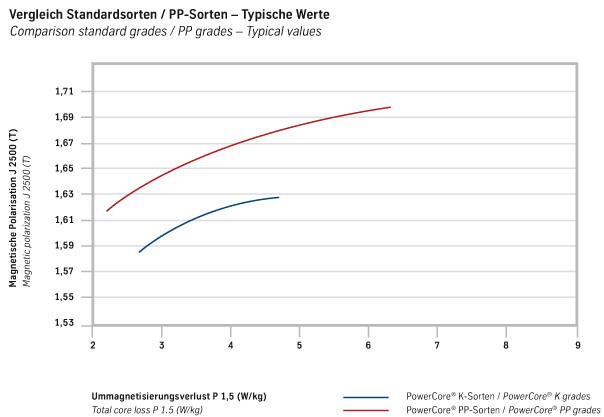

powercore® PP grades display a favorable isotropic texture in the sheet plane thanks to the use of specialized manufacturing technology. This texture results in higher polarization values. PP grades can be magnetized more easily at medium and higher field strengths. Due to the special composition, improved thermal conductivity is also achieved.

The magnetic properties are developed by annealing the individual stampings or the complete stack at the customer’s plant.

powercore® high permeability grades, non grain oriented, non finally annealed

| Grade | NOMINAL THICKNESS | DENSITY | MAX. CORE LOSS AT | MIN. POLARIZATION AT | |||||

|---|---|---|---|---|---|---|---|---|---|

| powercore® | [mm] | [kg/dm3] | 50 Hz 1.5 T [W/kg] |

50 Hz 1.0 T [W/kg] |

60 Hz, 1.5 T [W/lb] |

60 Hz 1.0 T [W/lb] |

[T] 2,500 [A/m] |

[T] 5,000 [A/m] |

[T] 10,000 [A/m] |

| 235-35PP | 0.35 | 7.60 | 2.35 | 0.95 | 1.35 | 0.55 | 1.49 | 1.60 | 1.70 |

| 280-35PP | 0.35 | 7.60 | 2.80 | 1.10 | 1.61 | 0.63 | 1.49 | 1.60 | 1.70 |

| 330-35PP | 0.35 | 7.65 | 3.30 | 1.30 | 1.90 | 0.75 | 1.49 | 1.60 | 1.70 |

| 270-50PP |

0.50 | 7.70 | 2.70 | 1.16 | 1.55 | 0.67 | 1.61 | 1.70 | 1.81 |

| 330-50PP |

0.50 | 7.75 | 3.30 | 1.60 | 1.90 | 0.92 | 1.61 | 1.70 | 1.81 |

| 390-50PP |

0.50 | 7.80 | 3.90 | 1.70 | 2.24 | 0.98 | 1.60 | 1.68 | 1.78 |

| 450-50PP |

0.50 | 7.80 | 4.50 | 2.00 | 2.58 | 1.15 | 1.64 | 1.72 | 1.82 |

| 660-50PP |

0.50 | 7.85 | 6.60 | 3.00 | 3.79 | 1.72 | 1.68 | 1.76 | 1.86 |

| 800-65PP | 0.65 | 7.85 | 8.00 | 3.50 | 4.60 | 2.01 | 1.68 | 1.75 | 1.87 |

powercore® K grades in comparison with powercore® PP grades