Selected pladur® products for multistory construction

For more information, click on a photo.

Overview of pladur® products by industry

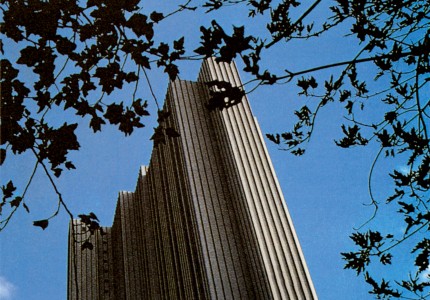

pladur® for multistory construction

pladur® for industrial buildings

pladur® for doors & gates

pladur® for home appliances

pladur® for commercial vehicles

pladur® for energy and solar industry

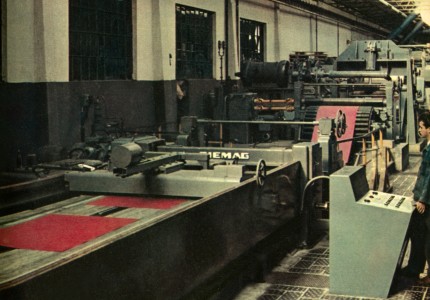

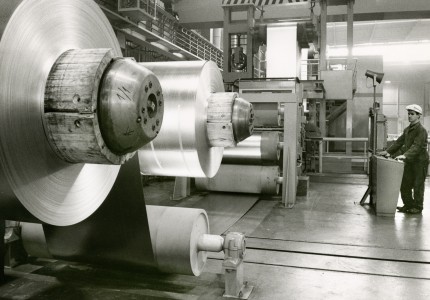

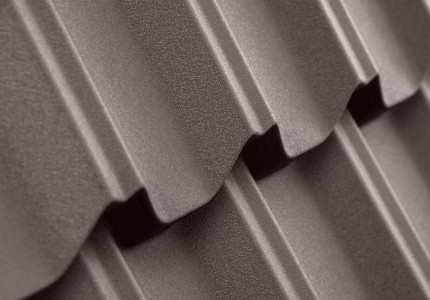

State-of-the-art coil coating technology: variety of colors and surfaces made of steel

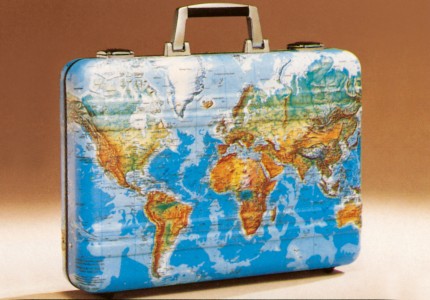

thyssenkrupp Steel has state-of-the-art, organic coil coating lines on which we manufacture our pladur® products in an environmentally friendly and resource-conserving manner. We are constantly expanding our portfolio. In doing so, we attach great importance to customer orientation: In all coil coating developments, we pay attention to the application area and function, and even adapt our products to the manufacturing process of our customers. The spectrum of surface finishes of pladur® ranges from deep matt through high-gloss, smooth, with a light texture modeled on nature down to custom designs. Bending, drawing, press braking, profiling, stamping and roll forming − our organic coil-coated strip and sheet can be shaped without any problems. Moreover, we set great store by protection: pladur® products from thyssenkrupp Steel are optimally protected against corrosion and UV radiation − and EDP-certified.

pladur® coil-coated products: technical information

Base material for pladur®: Mild steel

DIN EN 10130, DIN EN 10346

| SURFACE FINISHING | |||||

|---|---|---|---|---|---|

| Steel grade designation | Standard designation | -/UC | Z/GI | ZM | AS |

| DC01 | DC01 | ||||

| DX51D | DX51D | ||||

| DX52D | DX52D | ||||

| DX53D | DX53D | ||||

| DX54D | DX54D | ||||

| DX56D | DX56D | ||||

| Available -/UC: Uncoated Z/GI: Hot-dip galvanized ZM: ZM Ecoprotect® AS: Aluminum silicium coated |

|||||

Base material for pladur®: Micro-alloyed steel

DIN EN 10268

| SURFACE FINISHING | |||||

|---|---|---|---|---|---|

| Steel grade designation | Standard designation | -/UC | Z/GI | ZM | AS |

| HC300LA | HC300LA | ||||

| Available -/UC: Uncoated Z/GI: Hot-dip galvanized ZM: ZM Ecoprotect® AS: Aluminum silicium coated |

|||||

Base material for pladur®: High-strength IF steel

DIN EN 10346

| SURFACE FINISHING | |||||

|---|---|---|---|---|---|

| Steel grade designation | Standard designation | -/UC | Z/GI | ZM | AS |

| HX220YD | HX220YD | ||||

| Available -/UC: Uncoated Z/GI: Hot-dip galvanized ZM: ZM Ecoprotect® AS: Aluminum silicium coated |

|||||

Base material for pladur®: Structural steel

DIN EN 10 346

| SURFACE FINISHING | |||||

|---|---|---|---|---|---|

| Steel grade designation | Standard designation | -/UC | Z/GI | ZM | AS |

| S220GD | S220GD | ||||

| S250GD | S250GD | ||||

| S280GD | S280GD | ||||

| S320GD | S320GD | ||||

| S350GD | S350GD | ||||

| Available Further grades on request. -/UC: Uncoated Z/GI: Hot-dip galvanized ZM: ZM Ecoprotect® AS: Aluminum silicium coated |

|||||

Coating systems

| Substance class | Abbreviation1 | Coating material |

|---|---|---|

| Liquid coating | EP | Epoxy |

| SP | Polyester | |

| SP-PA | Polyamide modified polyester | |

| HDP-PS | High Durable Polymer Polyester | |

| PUR | Polyurethane | |

| PUR-PA | Polyamide modified polyurethane | |

| FEVE | Polyfluoroethylene / vinyl ether | |

| PVDF | Polyvinylidene fluoride | |

| Foil | PE (F) | Polyethylene (Foil) |

| PET (F) | Polyethylene terephthalate (Foil) | |

| PVC (F) | Polyvinyl chloride (Foil) |

Delivery forms and dimensions

| THICKNESS from_to in mm |

WIDTH from_to in mm |

LENGTH from_to in mm |

|

|---|---|---|---|

| Strip | 0.40 − 3.00 | 600 − 1,750 | |

| Sheet | 0.40 − 3.00 | 600 − 7,750 | 450 − 6,00 |

| Special dimensions | 0.25 − 2.00 | 100 − 640 | 100 − 7,000 |

| Slit strip | 0.40 − 3.00 | 20 − 599 | |

| Special dimensions on request. Not all thickness and width combinations are possible. |

|||