Innovative solutions for our customers

smart services

So this is what a meeting between development engineers could look like in future. Virtual Engineering is about reducing development time, hardware and expensive test series: Instead of the real crash vehicle, its digital twin drives against the wall - built from 3D data of extensive crash simulation calculations. “This reduces the development costs to a fraction of what is currently spent“, explains Erik Hilfrich, Team Manager in Application Technology at thyssenkrupp Steel. “What is more, we send data around the world, not bulky components. This facilitates collaboration with our international customers. We can, for example, examine vehicle crashes as often as required, in slow motion and at close range. This also allows us to better present our development work“. Hence, Virtual Engineering is also a tool that enables engineers to collaborate with customers and colleagues quickly and across national borders.

Data replacing material – a vision for the steel mill of the future? Volker Lang, Head of Digitalization & Architecture categorically rejects this scenario. “In our industry, things are a little different than in the automotive industry. Our customers have long since stopped buying only engineering skills, but also and above all high-tech computers on four wheels. We support this change by digitizing our core product steel. This means that we offer our customers – besides the classic material properties – also a higher service level, because our order processing has become more flexible. Therefore, data are also of central importance for us. It helps us to better meet customer expectations and to optimize both our products and our processes“.

The one thing that becomes clear at the locations of thyssenkrupp Steel is that digital transformation is an open-ended process. A process that innovators can initiate, but the implementation of which depends on the attitude and willingness to change of each individual employee. Getting the employees on board, sharing knowledge with them and dispelling their reservations are the most important tasks in every solutions-oriented digital project of thyssenkrupp Steel. Lars Bode from the Business Unit Automotive remembers the presentation of smartform® on a tablet, one of the first Augmented Reality applications in the company. The innovative smartform® process enables to produce components from ultra-high-strength steels with almost no springback. This can be depicted realistically and thus well illustrated on the tablet. “The simulation makes the exchange among experts on complex processes much easier. However, we also bring a component along, as an illustrative model, so to speak“. That makes sense - because data can be experienced, but not touched. By the time VR goggles have become established as a working tool, the machines in the rolling mills will probably have long since shared their data with the plants at other locations.

Refreshing soft drinks, hearty stews and hairspray that can withstand inclement weather – for all their differences in terms of content, these products often have one thing in common: in the supermarket, they are offered in cans made of tinplate, a thin cold-rolled steel sheet with a tin coating. You don't have to look far to find the reasons for its diverse use: Tinplate is an extremely safe packaging material, which ensures very long shelf life due to the one hundred percent protection against the effects of light and oxygen. In addition, its good processing capabilities and printability are factors in favor of the sustainable material, which can be recycled again and again in a closed material cycle.

The technical development capability of a product can never be fully exploited but there is always scope for further optimization; consequently, thyssenkrupp Rasselstein has been working for some time on making tinplate cans even more precisely tailored to the needs of its customers. The main driver is the desire to use materials even more efficiently. What is easy to say turns out to be extremely challenging in practice. Food cans have been with us for over two centuries. Over this immense period of time, the design has been adapted and improved countless times, so that when it comes to further optimization, the devil is in the proverbial details. "Our primary levers for further development are process and geometry adjustments," explains Dr. Manuel Köhl, Head of Application Technology at thyssenkrupp Rasselstein, the only tinplate production facility in Germany.

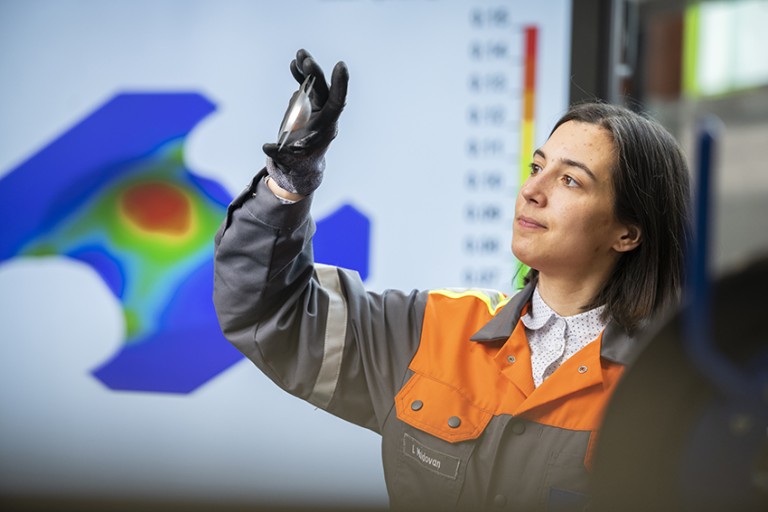

The problem: even the smallest changes to the starting material have a major impact on processability. Machines and tools must be adapted to new material properties, as it is not possible to predict how the packaging steel will behave under changed conditions – such as reduced thickness. "This is where the Finite Element Analysis (FEA) comes into play as a new approach," says Rasselstein's development engineer Ioana Weinand. For her, the process already tested in the automotive industry is characterized by the fact that product development and optimization are significantly accelerated by means of virtual analysis of forming and stability processes. Weinand: "The 'trial and error' procedures that are common in the industry can be reduced or even completely avoided in this way." This is a significant step forward, as in earlier days real sample cans had to be produced by the dozen, sometimes even by the hundred, in order to test the feasibility of new concepts.

"By means of FEA, our customers know even before processing a thinner or innovative packaging steel whether certain ideas for material reduction can also be implemented in practice," explains Ioana Weinand. As part of an overarching digitization strategy, she has actively shaped the development of FEA at thyssenkrupp Rasselstein in various roles from the very beginning. In her previous job as an engineer at the thyssenkrupp Steel site in Dortmund, the 32-year-old was part of a cross-company transfer program that focused on research into new development processes in the area of packaging steel. At thyssenkrupp Rasselstein in Andernach, she is now seamlessly continuing her work as part of a highly specialized team that aims to shape an entire industry with the Finite Element Analysis.

Dr. Manuel Köhl: "We will therefore devote even more attention to the topic of FEA in the future, because we want to be at the forefront of the further development of this innovative technology. Soon it will be impossible to imagine life without the Finite Element Analysis." The fact that the importance of FEA is increasing is also due to its versatile application possibilities. Already today, the virtual method can be applied to all can types and components. This includes aerosol can ends and bottoms, as well as twist-off closures or crown corks. Fabian Knieps, who works as a PhD student in development at thyssenkrupp Rasselstein, sees additional opportunities for the industry here: "FEA makes it possible to implement completely new product ideas and thus promotes innovation in the packaging industry. Manufacturers can be more daring and come up with more creative solutions."

Trivium Packaging, a global leader in the manufacture of tinplate packaging, sees FEA as a great opportunity for virtual product and process simulation. Virtual simulations like FEA can increase the efficiency of our product development and provide the market with better packaging solutions," said Jean-Luc Keravec, Vice President Group R&D, Trivium. "The material description Rasselstein provided for the FEM was critical. This project shows: by bringing together open-minded and passionate people with the appropriate skills, real progress can be made, benefiting both people and the planet. Rasselstein is proving to be a partner that listens, speaks the same technical language and shares our passion for innovation."

But other companies in the tinplate packaging value chain, such as MAIKO Engineering from Braunschweig, also see the advantages of the method. "For us toolmakers, virtual methods represent an opportunity to optimize our products. Here, we rely on close cooperation with thyssenkrupp Rasselstein and complement one another. For example, in a joint project we were able to analyze various forming processes in detail using optical measurement methods. This helps us to better understand the processes and accelerates process and product development," explains Marco Hein, Managing Director of MAIKO Engineering.

Contact FEM

Manuel Köhl

Head of Application engineering, thyssenkrupp Rasselstein GmbH

Telephone: +49 2632 30974950

Send emailContact Digitalization

Volker Lang

Head of Digital Transformation & Innovation

thyssenkrupp Steel Europe AG

Kaiser-Wilhelm-Strasse 100

47166 Duisburg

Telephone: +49 (0)203 52-47749

Send email

thyssenkrupp Steel Europe

Marcus van Marwick

Head of Communications, Marketing & Sustainability

Telephone: +49 203 52 41005

Send email