The two new developments are characterized by very low remagnetization core losses of 12.5 watts per kilogram and 13 watts per kilogram, respectively. This means we've been able to improve them by up to 11% compared to current reference grades. Of course, the other magnetic parameters of the new grades, for example polarization, also achieve peak values. The series ramp-up of the new NO25 grades in the new plants is planned; sampling and homologation inquiries can be made immediately.

The electric motor is the heart of the electric vehicle, and electrical steel is indispensable for the electric motor. powercore® traction electrical steel strip has been specially developed and optimized for the high demands of electric mobility. David Pieronek, Product Manager for Electrical Steel at thyssenkrupp Steel Europe, explains what the high-tech material can do, how different motor types and drive systems affect the demands placed on it, and what the consequences are.

1. What is powercore® traction?

Our powercore® traction electrical steel is the logical further development of our non-oriented (NO) electrical steel for the high demands of electric mobility: High efficiency for long ranges, high torque for maximum driving dynamics, and all this under high cost pressure.

2. How does electrical steel strip drive the electric motor?

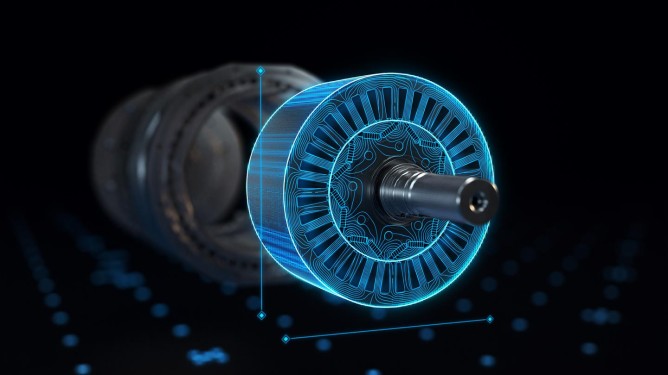

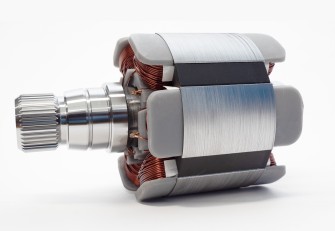

Our powercore® traction grades are used to build what are referred to as rotors and stators. In the process, our grades amplify and direct the magnetic flux in the coils. Typically, a rotating magnetic field is generated on the outside of the stator, which is followed by the rotor on the inside. However, there are very different motor types and drive philosophies in current electric vehicles. Asynchronous machines and synchronous machines, permanently excited – i.e. with magnets – or separately excited, with single-speed or multiple-speed gearboxes. Each combination results in a different requirement profile for the electrical steel strip. Therefore, powercore® traction also stands for a product family with various different grades. We operate our own motor test bench in our Application Technology department, where we test our powercore® traction grades in the various motor types. This enables us to provide our customers with the best possible advice on selecting the right grade depending on the customer's specific requirements.

3. What properties must the electrical steel strips have for this?

As already mentioned, this depends very much on the respective motor and drive concepts. The trick is to always ideally match the 3 core requirements of low power dissipation, high polarization and mechanical strength to each respective application of our customers, in addition to many other requirements. A basic requirement that always applies is to achieve properties that are as homogeneous as possible over the strip length and width. This applies to the magnetic properties as well as to the mechanical properties and geometric tolerances, which are highly relevant for the die cutting and packaging processes.