Trade press, Daily press, 2018-06-11, 04:54 pm

On the “Day of Packaging”, students learn about the sustainability of packaging steel

Sustainability was the central topic at this year’s “Day of Packaging”. And what could be more obvious than to ask thyssenkrupp Rasselstein GmbH, Germany’s only packaging steel manufacturer, about the production and recycling of tinplate. About 30 students and teachers from Andernach, Neuwied and Mülheim-Kärlich took the opportunity to collect information on packaging steel, the recycling “champion”, at the fourth national “Day of Packaging”. Champion due to the fact that in 2016, 91 percent of used tinplate packaging was recycled in Germany. For many years, this recycling rate has put packaging steel well-ahead of other packaging materials.

This day, initiated by the German Packaging Institute dvi, as well as its focus on “sustainability” struck a chord with the Andernach-based company. The packaging and filling industry has long known that tinplate, as a “permanent material”, retains its properties without a loss of quality, even after being reused many times, and can therefore be recycled excellently. On the “Day of Packaging” this fact could also be shown to the young visitors. “Used tinplate packaging is collected, sorted, bundled, prepared and used in the form of quality scrap for high-quality recycling within a closed material loop,” states Christian Pürschel, Head of Communications and Market Development at thyssenkrupp in Andernach. “It is important to raise awareness among young people that a tinplate can is not a disposable product, but rather is used in a closed material loop to produce new steel products. Steel scrap and primary resources such as iron ore, coking coal and limestone are turned into new steel in the steelworks.” The use of each ton of steel scrap saves about one ton of CO2 emissions.

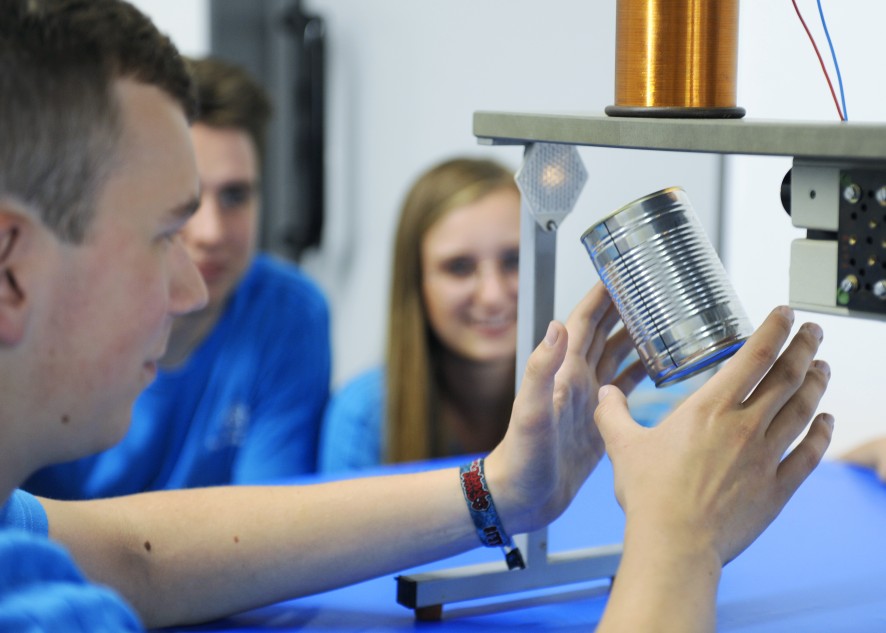

Just as in previous years, the thyssenkrupp trainees in Andernach presented the high-tech packaging material and the production processes from their point of view. And so there were no reservations when answering the questions of interested students. For the first time, the event also included an exhibition on recycling and food waste. The students learned how a can is produced and filled, why the use of canned food can reduce food waste and why primary resources and energy can be saved by diligently collecting cans in the “yellow waste bag” at home and by returning beverage cans via the deposit system.

At the end of a very exciting and informative day, the students left the company with a lot of impressions, a great deal of new expertise and a money box which they had closed themselves. “Once again, the event was a complete success”, concludes Pürschel.

About us:

thyssenkrupp produces approximately 1.5 million tons of packaging steel each year in Andernach, Rhineland-Palatinate, Germany. At the largest site of this type in the world, thyssenkrupp rolls steel to a thickness of 0.100 millimeters and finishes the surface with tin or chrome. Nearly all of the steel produced is shipped to packaging manufacturers around the world. Alongside cans for food and pet food, packaging steel is also used, for example, for beverage and aerosol cans, containers for chemical and technical goods, as well as for crown corks and twist-off closures. thyssenkrupp has around 2,400 employees in Andernach.

Company blog:

https://engineered.thyssenkrupp.com/en