Trade press, Daily press, 2018-08-31, 05:00 pm

Strong signal for innovation and employment in the Ruhr: thyssenkrupp Steel decides to build a new hot-dip galvanizing line in Dortmund

- New line will serve rising demand from automotive OEMs for premium hot-dip coated products

- Innovative high-quality zinc-magnesium coatings can also be produced on the new line

- Investment in the low three-digit million range

- Will create over 100 highly skilled jobs

- Start-up planned for early 2021

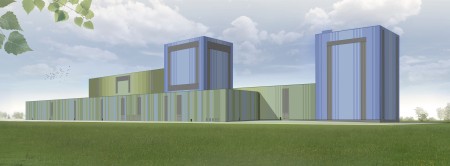

thyssenkrupp has cleared the way for the construction of a new state-of-the-art hot-dip galvanizing line at its Dortmund site: as of yesterday all the necessary internal approvals are in place. Provided the district government in Arnsberg grants the Duisburg-based steel producer building permission, the first coils of hot-dip galvanized steel could roll off the new line as soon as early 2021. thyssenkrupp Steel’s tenth hot-dip coating line will create over 100 new and skilled jobs in the Ruhr and represents an investment in the low three-digit million range.

Important strategic step geared towards attractive product markets

The new hot-dip coating line at thyssenkrupp Steel will support the auto industry trend towards hot-dip galvanized products. “As a close partner to our customers we understand the rising demand for premium hot-dip galvanized materials and will meet it in the best possible way. With the new line we want to further strengthen our position in an essential important market segment,” says Andreas Goss, CEO of thyssenkupp Steel. “The investment is clear evidence of our strategy to focus on innovative technologies and markets with potential and to secure the future of our business,” adds Goss. The new line will also make zinc-magnesium products, which are particularly in demand from auto manufacturers. thyssenkrupp was the first steel producer in the world to offer all the coatings commonly used in the auto industry with outer panel quality.

Decision in favor of Dortmund and the Ruhr as a center of industry

There are good reasons for choosing Dortmund as the location. There is already a hot-dip coating line here – FBA8 – which started operation in 2001 and is regarded as one of the most modern and efficient of its kind. The new line will be built right next to the existing one to allow them to share technical and supply services. The new unit will increase the site’s capacity for hot-dip coated products by 500,000 tons to a total of one million tons. Including thyssenkrupp Steel’s in-house research centers in Duisburg and Dortmund it will make the Ruhr Europe’s biggest center of excellence for hot-dip galvanized products. Prof. Dr. Andreas Pinkwart, Minister for Economic Affairs and Digitization, welcomes the new investment: “The new hot-dip coating line will not only strengthen the Ruhr region as an industrial cluster; the use of innovative technologies is essential for the international competitiveness of our steel industry – we will only succeed on the world market if we offer the best quality. thyssenkrupp Steel is creating ideal conditions for sustainable jobs in North Rhine-Westphalia.”

Existing jobs secured – new jobs planned

The new hot-dip coating line will create over 100 additional jobs in Dortmund and further secure existing jobs. The new jobs will also offer excellent development opportunities for various engineering and apprentice professions. “The investment in FBA10 is an investment in the future of the steel industry in the Ruhr and the future of our company. After many months of uncertainty, this is an important and necessary signal. It also shows that despite all the talk about savings and job cuts we are also looking to strengthen and grow our sites in targeted fashion,” says Tekin Nasikkol, General Works Council Chairman of thyssenkrupp Steel Europe.