PV parking lot canopies made of strip galvanized steel

The energy and mobility transition continues to progress and is leaving ever more visible traces in public infrastructure. In most federal states - including Baden-Württemberg, North Rhine-Westphalia and Rhineland-Palatinate, for example - newly built, commercially used parking spaces above a certain number of parking spaces must already be equipped with photovoltaic systems. Other federal states want to introduce similar regulations and a general photovoltaic obligation for newly built parking spaces is also being discussed at federal level.

The installers and operators of such solar-covered parking spaces - for example in front of DIY stores, shopping centers or in industrial areas - face a number of challenges with the new legal requirements. Among other things, it is important to find the right material for the supporting structure of solar carports. "The average lifespan of a solar system is between 20 and 25 years. In view of these long lifetimes, high-performance steel substructures are required for the modules of ground-mounted PV systems in particular," says Arne Schreiber, Product Manager at thyssenkrupp Steel.

ZM Ecoprotect® Solar for solar carport mounting systems: Effective protection against corrosion

Arne Schreiber and the application technology team have examined the application of solar carports in detail. The result: ZM-coated steels from thyssenkrupp Steel in particular are ideal for the new application. The most important aspect here is the material's particular resistance to corrosion attack. “ZM Ecoprotect® Solar with a suitable coating offers particularly effective and long-lasting protection under high corrosive loads, which is significantly more effective than conventional hot-dip galvanizing,” explains expert Sophie Merling from Surface Development at thyssenkrupp Steel. The zinc-aluminum-magnesium alloy plays a key role in providing efficient and durable protection through an electrochemical mechanism. To this end, extensive tests were carried out in the corrosion testing and electrochemistry laboratories, generating an in-depth understanding of the product, which ultimately benefits customers.

In addition to good corrosion protection, there are other aspects that make ZM Ecoprotect® Solar the first choice for weather-resistant support structures for solar installations. As part of its development work, thyssenkrupp Steel has ensured that the product can also be excellently processed with higher coating thicknesses. Merling: "ZM-coated steels are very easy to form, especially for roll forming. Thanks to the harder surface compared to zinc coatings, significantly less abrasion is generated in the tool, thus reducing wear on the machining tools."

Versatile grade portfolio of ZM-coated steels for all requirements

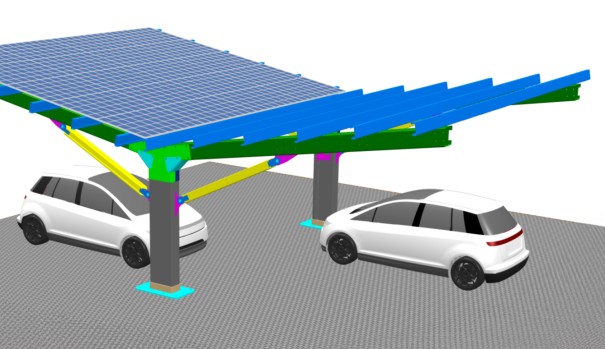

The customer benefits of ZM Ecoprotect® Solar become particularly clear in the holistic view: Using the example of the roof construction of a solar carport, the ZM project team was able to show that the substitution of a roll-formed and then piece-galvanized double T-beam with a roll-formed profile with ZM Ecoprotect® Solar enables considerable weight and material savings with cost advantages and a significantly improved life cycle analysis (LCA).

Advantages of roll-up profiles made of ZM Ecoprotect® Solar compared to piece-galvanized double T-beams for solar carports

- Weight reduction:

Roll-up profiles are often lighter than double T-beams, which reduces the overall weight of the structure as well as transport and logistics costs. - Material savings:

Thanks to the optimized design of the roll profiles, less material is required to achieve the same load-bearing capacity as with T-beams. - Environmental friendliness:

Due to the reduced amount of material and more efficient production, roller profiles have a lower CO2 footprint. - Costs:

Replacing batch galvanizing with strip galvanizing not only saves costs, but also significantly shortens the logistics chain, as the formed profiles do not have to be galvanized afterwards.

In terms of sustainability, the values can be further improved if customers use CO2-reduced steel from thyssenkrupp Steel - the entire ZM Ecoprotect® Solar portfolio is also available as CO2-reduced bluemint® Steel. Arne Schreiber: “We know the high demands our customers place on the durability and processing of PV mounting systems for carports and offer a versatile portfolio of grades with a high-quality ZM coating – with a 25-year guarantee against rusting through, depending on the corrosion load.”

ZM Ecoprotect® Solar: Available steel grades, coatings and dimensions for solar carport systems

Hot-dip coated structural steel

DIN EN 10346

| Dimensions | |||

|---|---|---|---|

| Steel grade designation |

Coatings in g/m2 |

Thickness1 from _ to in mm |

Width1 from _ to in mm |

| S220GD |

ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S250GD |

ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S280GD |

ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S320GD |

ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S350GD |

ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S390GD | ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S420GD | ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S450GD | ZM310, ZM430 | 0.60 – 4.00 | 700 – 1,560 |

| S550GD | ZM310, ZM430 | 1.80 – 3.00 | 700 – 1,560 |

Mild steel

DIN EN 10346

| Dimensions | |||

|---|---|---|---|

| Steel grade designation |

Coatings in g/m2 |

Thickness1 from _ to in mm |

Width1 from _ to in mm |

| DX51D | ZM310, ZM430 | 0.60 – 3.00 | 700 – 1,560 |

| DX52D | ZM310, ZM430 | 0.60 – 3.00 | 700 – 1,560 |

| DX53D | ZM310, ZM430 | 0.60 – 3.00 | 700 – 1,560 |

| DX54D | ZM310, ZM430 | 0.60 – 3.00 | 700 – 1,560 |

| DX56D | ZM310, ZM430 | 0.60 – 3.00 | 700 – 1,560 |

Micro-alloyed steel

DIN EN 10346

| Dimensions | |||

|---|---|---|---|

| Steel grade designation |

Coatings in g/m2 |

Thickness1 from _ to in mm |

Witdh1 from _ to in mm |

| HX260LAD | ZM310, ZM430 | 0.40 – 6.00 | 700 – 1,560 |

| HX300LAD | ZM310, ZM430 | 0.40 – 6.00 | 700 – 1,560 |

| HX340LAD | ZM310, ZM430 | 0.40 – 6.00 | 700 – 1,560 |

| HX380LAD |

ZM310, ZM430 | 0.40 – 6.00 | 700 – 1,560 |

| HX420LAD | ZM310, ZM430 | 0.40 – 6.00 | 700 – 1,560 |