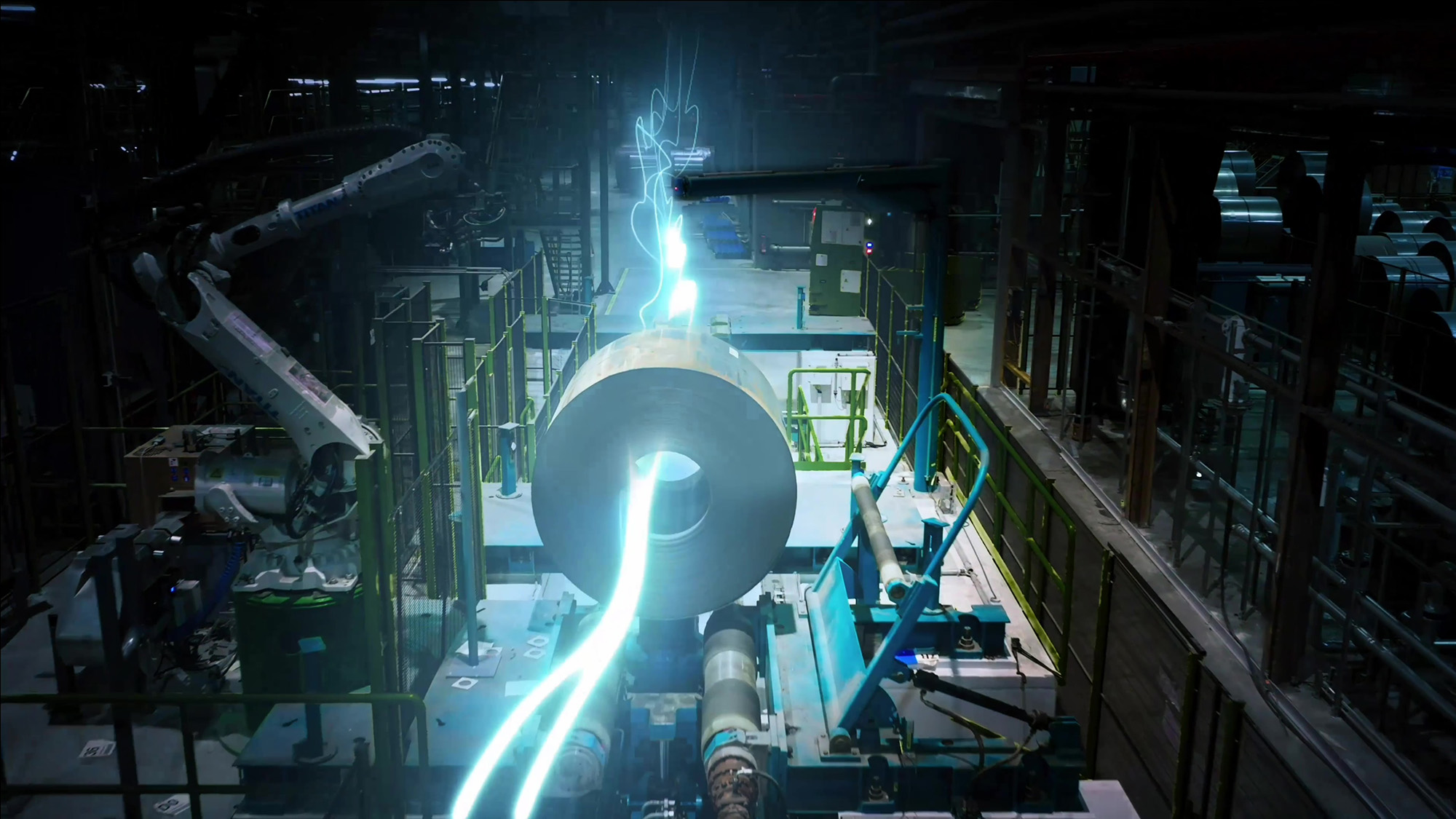

Our electrical steel portfolio at a glance

With our two product areas, non grain oriented and grain oriented electrical steel, we offer innovative steel grades that meet high sustainability requirements while ensuring maximum performance and efficiency.

Non grain oriented electrical steel (NO)

Non grain oriented electrical steel is a soft magnetic steel with uniform magnetic properties in all directions. It is developed for applications that require variable magnetization, such as electric motors and generators. It is also characterized by its versatility and adaptability to different operating conditions."

Characteristics:

- Isotropic magnetic properties

- Versatile applications for changing magnetic fields

- Outstanding efficiency and resource conservation in rotating engines

Application examples:

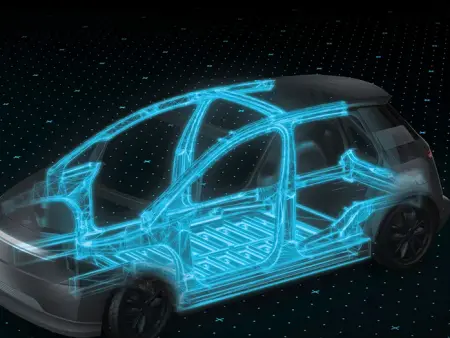

- Electromobility: electric motors for vehicles that require high efficiency and performance

- Household appliances: Motors in washing machines, hair dryers or air conditioners

- Generators: Energy generation in plants that are flexibly dependent on changing magnetic fields

No energy transition without electrical steel: With our material for mobility, the non grain oriented electrical steel powercore® and powercore® traction, we ensure sustainable mobility on rail and road, greater energy efficiency and the generation of renewable energies.

Georgios Giovanakis, Head of Sales, thyssenkrupp Steel Europe AGGrain oriented electrical steel (GO)

As a leading manufacturer of GOES, thyssenkrupp Electrical Steel is actively contributing to the decarbonization of power grid value chains.

With the bluemint® steel grades, CO2 emissions during production can be reduced by up to 50%. GOES is used especially in transformers where magnetization takes place in a specific direction, which ensures high energy efficiency and low losses. thyssenkrupp Electrical Steel thus plays a central role in the energy transition.

Characteristics:

- Optimized magnetic properties in the rolling direction

- Minimal energy losses, low core losses

- High suitability for stationary applications with constant magnetization requirements

Application examples:

- Transformers: Power transmission with minimal losses, e.g. in mains and distribution transformers

- Large generators: Efficient conversion of energy in large power plants

- Charging infrastructure (electromobility): Stationary transformers in charging stations for electric vehicles

Grain oriented electrical steel is at the heart of modern transformers. With bluemint® powercore®, we provide the basis for maximum energy efficiency and drive the energy transition."

Angelo di Martino,CEO thyssenkrupp Electrical Steel GmbH