Transparent classification for CO2-reduced steel

The standard considers the entire production chain (cradle-to-gate) – from raw material extraction and energy input to the use of scrap. The classification is based on two key data points:

- The CO2 value per ton of hot-rolled steel, and

- The scrap content used in production.

Both values are calculated according to the specifications in the LESS rulebook. This makes the decarbonization progress of different production routes measurable and comparable. For companies, customers, and policymakers, LESS creates a transparent foundation to objectively evaluate progress toward climate neutrality.

Key takeaways:

- Standard for classifying low-emission steel

- Considers the entire production chain, including scrap content

- Creates transparency for industry, policymakers, and customers

Why LESS is so important for the steel industry – basis for green lead markets

A standard for more climate protection and innovation

Steel production accounts for approximately 7–9% of global CO2 emissions – around 5% in Europe. The Low Emission Steel Standard (LESS) is a crucial tool to sustainably reduce these figures.

LESS provides reliable, verifiable data on emission intensity and recycling rates and enables direct comparison of primary and secondary steel production using a recognized sliding scale approach. This makes progress in decarbonization transparent, measurable, and traceable.

With its technology-neutral approach, LESS promotes innovation and creates a level playing field in the transformation towards the corporate goal of Net Zero 2045. In addition, the LESS approach has created a basis for the introduction of green lead markets.

Advantages of the LESS Standard:

- Supports climate goals and decarbonization by 2045

- Enables comparison of different production routes

- Promotes technological innovation

- High transparency for customers and decision-makers

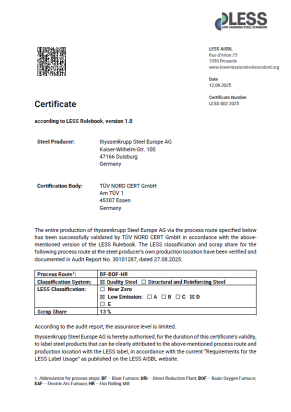

Our LESS certification – Living responsibility for climate-friendly steel

thyssenkrupp Steel receives first LESS certificate and drives forward CO2 reduction in steel production

thyssenkrupp Steel actively contributed to the development of the LESS system and successfully completed the first pilot certification for the primary production route.

The verification was carried out by TÜV Nord. This confirms our consistent efforts to reduce CO2 emissions in steel production.

For us, the LESS certification is more than just a recognition – it is proof of our future-oriented strategy and documents our progress toward “near-zero emission steel.”

Customer benefits of LESS at a glance:

- Evidence of concrete emission reduction measures

- Trust through independent verification

- Transparency and future security for customers and partners

- Reflects the transformation toward green steel

Current LESS classification for hot-rolled steel from thyssenkrupp Steel

Label D – State of the Art with a Measurable Contribution to the Circular Economy

Our steel has been certified under the blast furnace route with the LESS Label D.

With a scrap content of 13% calculated according to LESS, we are making a demonstrable contribution to the circular economy. This classification corresponds to the current state of the art, but already shows initial improvements in emission values. The scrap content is calculated according to the LESS methodology, which differs from the recycled content calculation method. The individual regulations must be taken into account for precise differentiation.

With the implementation of further transformation steps – especially through the use of a hydrogen-based direct reduction plant (bluemint® Steel) – we aim to gradually achieve higher LESS categories:

- Category C during the transition phase (natural gas operation),

- Category B in mixed operation (natural gas and hydrogen),

- Category A with hydrogen-based direct reduction, and

- Long-term “Near Zero” after full decarbonization of the upstream chain.

The LESS certificate can be found in the download section (on the right) of this website.

LESS in practice – principles & characteristics

Technology-neutral, transparent, and future-oriented

LESS is technology-agnostic – what matters are the actual emissions and the realized scrap content.

The standard thus takes into account both primary and secondary routes and contributes to the fair consideration of scrap resources.

With a clearly defined transformation logic—from “low-emission steel” to “near-zero emission steel”—LESS creates transparency, steers market mechanisms in favor of climate-friendly products, and establishes a basis for calculation on which green lead markets can be built.

Core principles of LESS:

- Technology-neutral approach

- Focus on actual emissions data and recycling content

- Combination of intermediate goals and a long-term climate vision

- Promotion of the circular economy

LESS in the European context

A standard from Germany – for climate-neutral steel production in Europe

LESS was initiated in Germany and developed in dialogue with industry, science, and policymakers.

Today, the standard is managed by the independent organization LESS aisbl, based in Brussels, which is responsible for its ongoing development, certification recognition, and data transparency.

LESS has now become established across the EU and is supported by numerous leading steel producers – from blast furnace to electric arc plants.

Key facts LESS:

- Originated in Germany, now a European standard

- Managed by an independent organization in Brussels

- Broad support from steel companies across Europe

- A pioneer for a climate-neutral industry