Good local and global forming properties

They combine good local and global forming properties. High elongation at fracture as well as good hole expansion capability and high resistance to edge compression failure allow for the first time more complex component geometries with high stretching and deep-drawing proportions in the forming process, thus tapping new cost-reduction and lightweight construction potential. Like the conventional dual-phase steels of this strength class, the new grades are protected against corrosion by the proven hot-dip galvanizing process.

Electromobility involves high crash behavior requirements

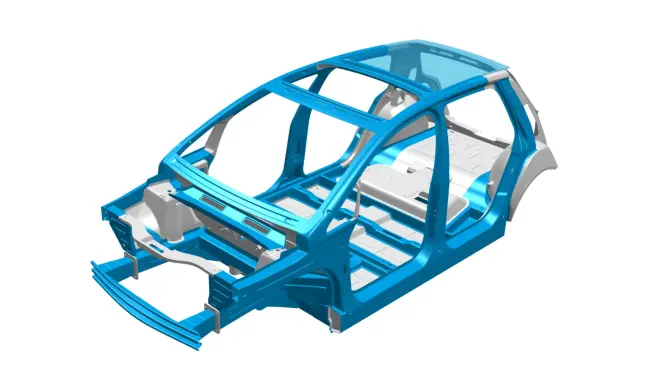

Lightweight construction still plays an important role also in vehicles with electrified powertrains. Although more kilos in electric cars are not necessarily tantamount to more emissions, and thanks to recuperation, the range is not affected to any significant extent either, crash scenarios of heavy battery vehicles pose new challenges for developers in the automotive industry and materials researchers alike. Both head-on collisions and rollovers are an enormous mechanical load on the car body structure. Strength alone is of limited use in the design of components such as side members and A-pillars, only in combination with a high energy absorption can optimum crash performance of these structures be achieved. Given their significant higher ductility, AHSS grades of the 3rd generation will in future play an important role in the development of electric vehicles with maximum car occupant safety. And research continues unabated. Patrick Kuhn: “JFE Steel Corporation and thyssenkrupp will soon be aiming their research and development work towards achieving even greater tensile strengths.”

Product range

jetQ®

| SURFACE FINISHING | ||

|---|---|---|

| Steel grade | Reference grade VDA 239-100 |

Z/GI |

| jetQ® 700Y980T |

CR700Y980T-DH | |

| jetQ® 850Y1180T | CR850Y1180T-FH | |

Z/GI: Hot-dip zinc coating