New, ultra-high-strength, hot-rolled multiphase steels CH-W® 700Y950T and CH-W® 750Y950T for the chassis now in series production.

Discover now

AHSS steels of 3rd generation: jetQ® – new ultra-high strength steels for geometrically complex crash structures

Discover now

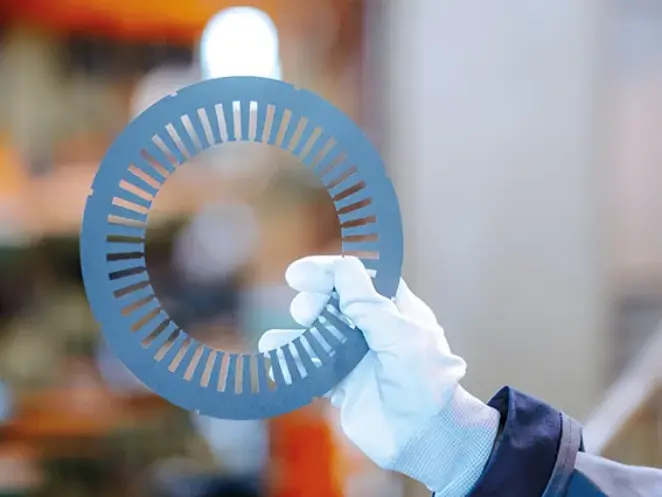

New premium grade: powercore® traction NGO 025-125Y420

Discover now

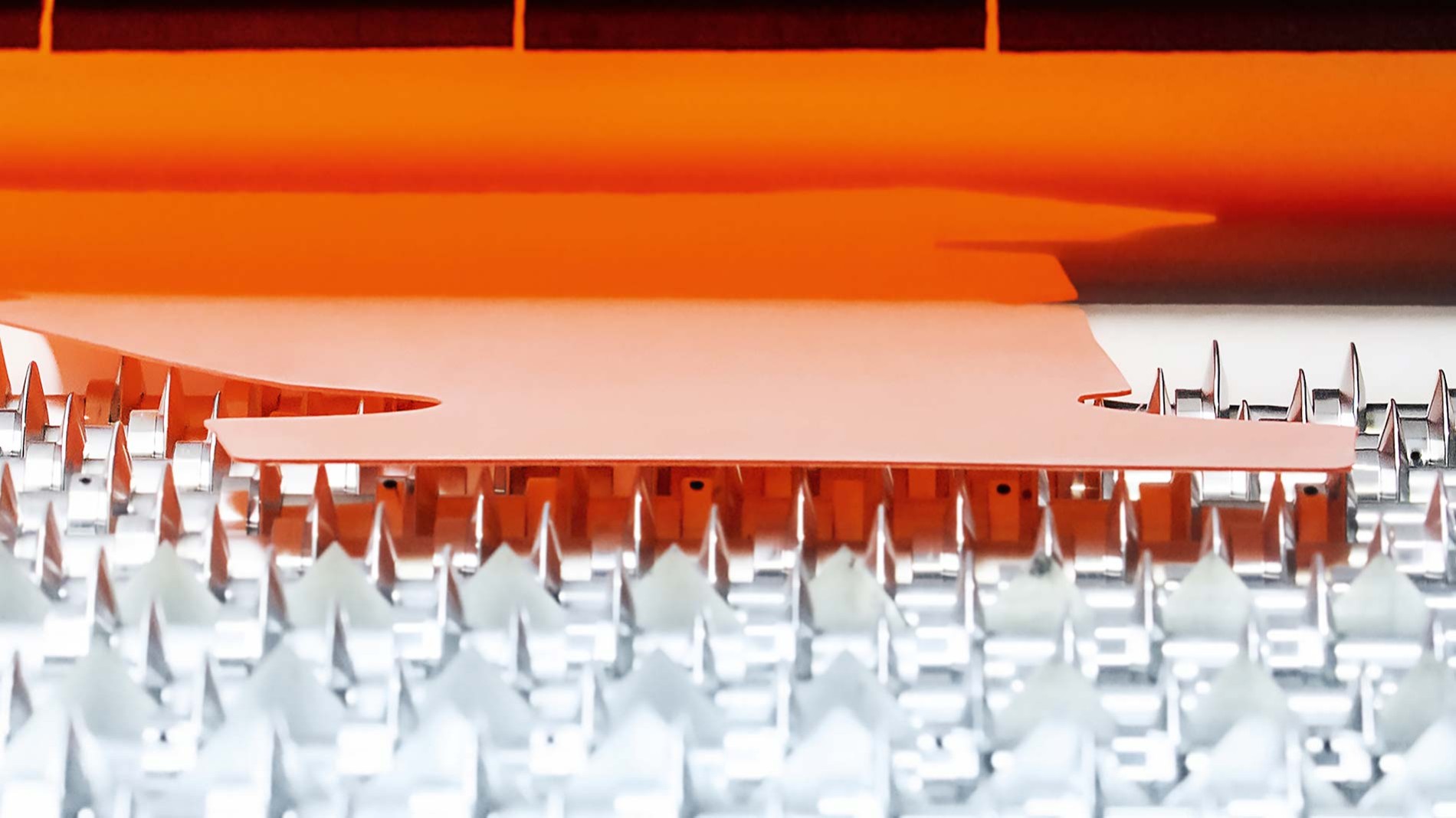

Composite material bondal®: acoustics optimization for electric motors

Discover now

For safe and lightweight seating structures: uncoated high-strength multiphase steels

Discover now

Service: Our application technology – for individual consulting as well as technical and economic concept work

Discover now

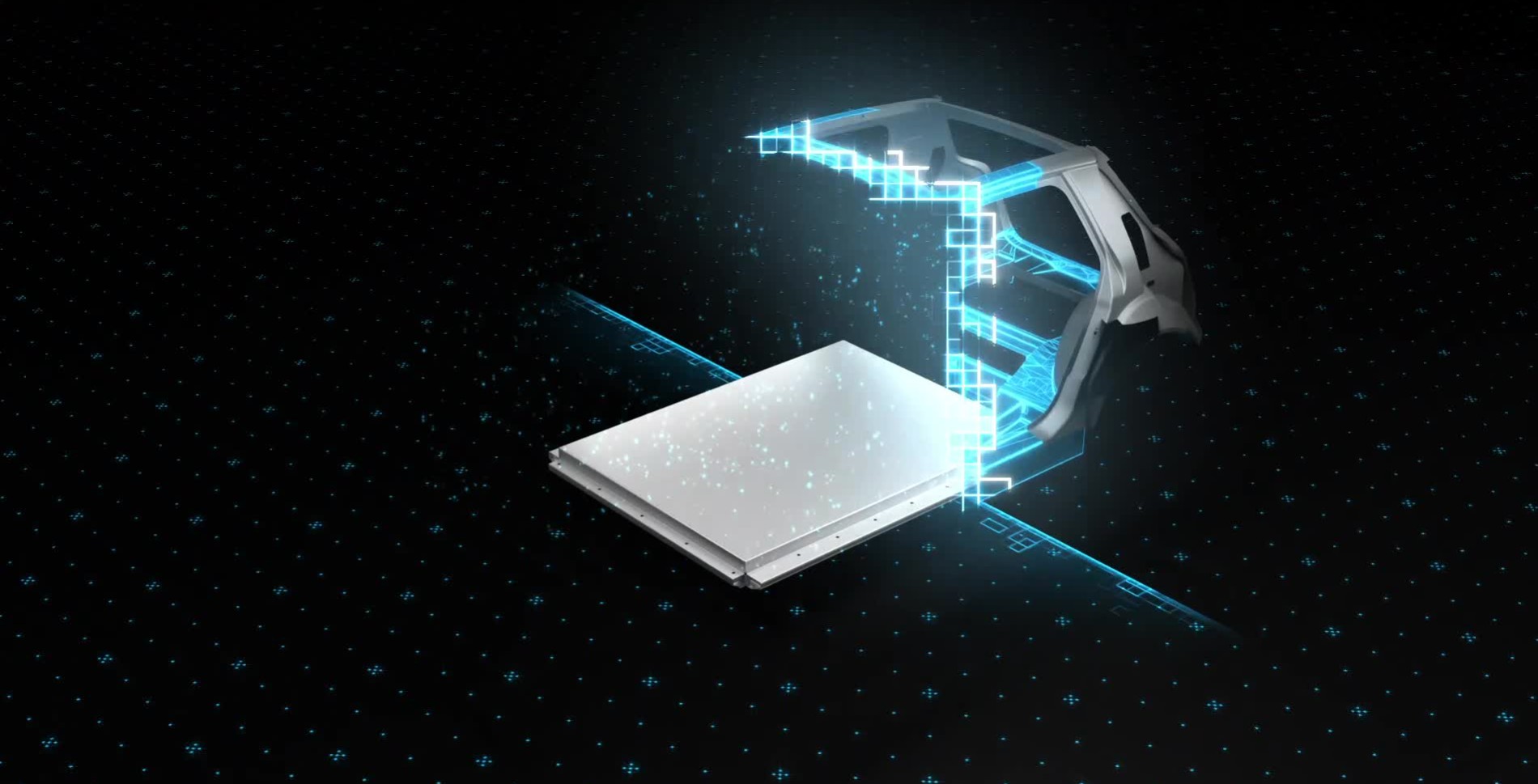

Areas of application in the automotive industry

Maximum safety and cost efficiency as well as sustainability are three important issues for the automotive industry. As a long-standing materials partner we are familiar with these requirements and offer comprehensive industry-specific materials and technology expertise.

Interior: steel concepts for lightweight seat structures

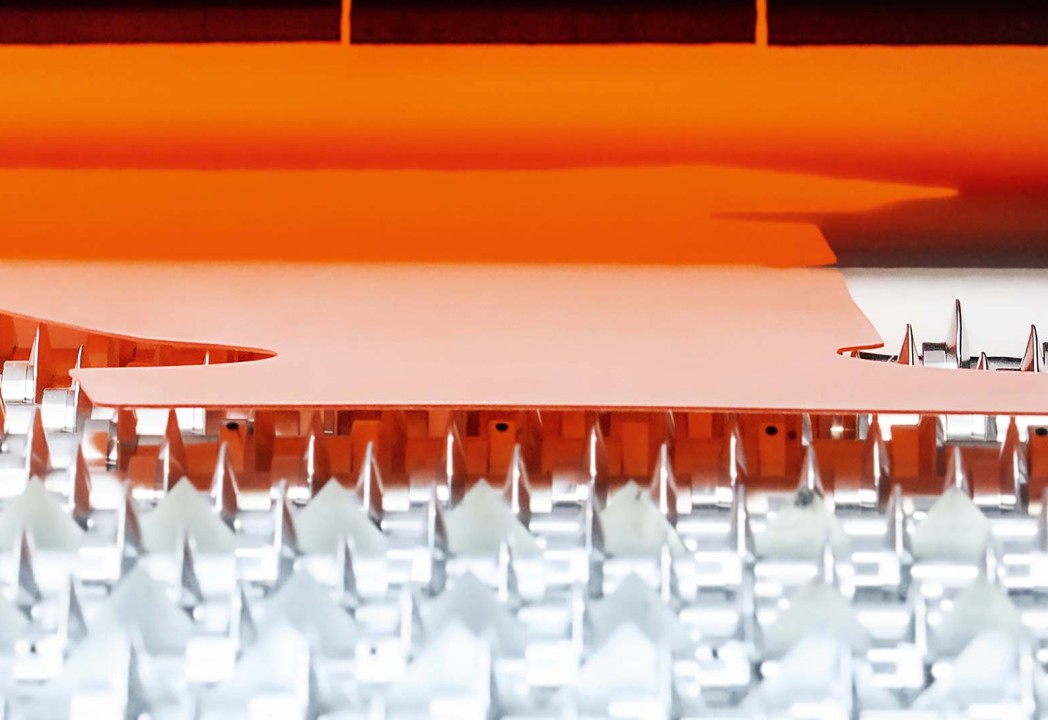

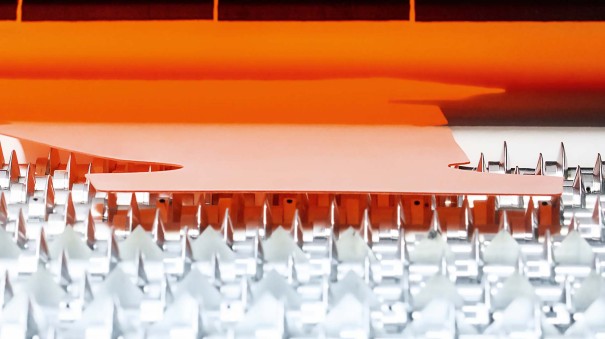

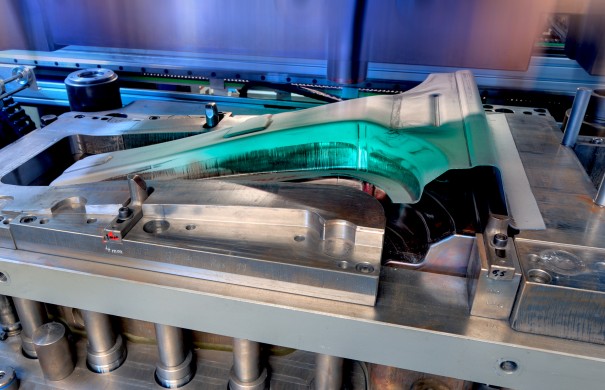

Chassis: hot-rolled lightweight steels with excellent workability

Outer skin: premium surfaces

Body: high-strength steels for hot stamping plus tailored services

Body: innovative AS Pro coating for hot stamping

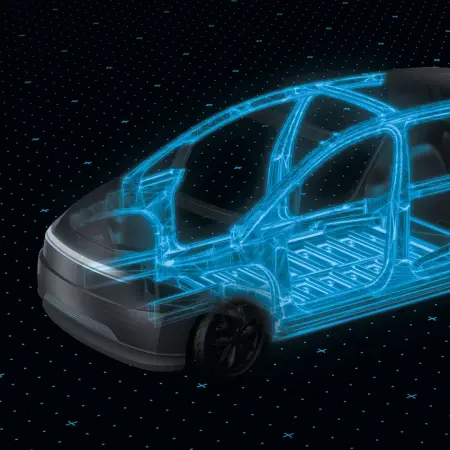

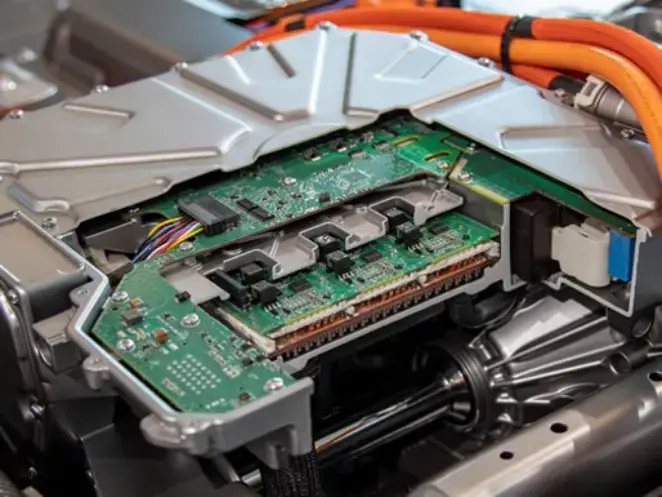

Powertrain, body and chassis: steel solutions for electromobility