The innovative Crash Management System, which has been jointly developed by the automotive supplier and the steel supplier is lighter and more cost-effective. The press-hardenable manganese-boron steel MBW-K® 1900 made by thyssenkrupp Steel is used in the novel Crash Management System by KIRCHHOFF Automotive.

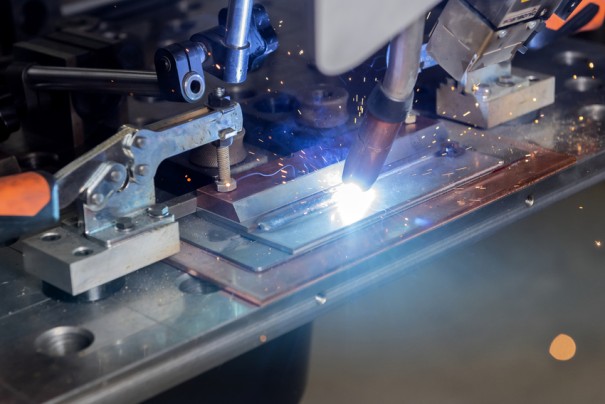

Silicate deposits on weld seams can be significantly reduced in the future thanks to an improved welding process for metal active gas welding (MAG) and an optimized pickling process.

As part of a research project, thyssenkrupp Steel is working together with partners to develop hybrid materials made of steel and plastic. Lightweight materials construction is the order of the day – especially in the automotive industry. That’s because lightweight cars consume less fuel, which reduces CO2 emissions.

A prominent example of a long-term strategic partnership is the establishment of the Interdisciplinary Center for Advanced Materials Simulation (ICAMS) at the Ruhr University in Bochum. ICAMS is a one-of-its-kind development center in Europe for new high-tech materials.

The "Advanced Materials Simulation" used in Bochum is a key innovative technology in materials development. The objective of ICAMS is primarily to model new materials on the computer and predict their properties by simulation. Using a multiscale approach, all of the dimensions relevant to the materials are incorporated into the simulation – from the atomic structure, through the microstructure to the macroscopic properties. In collaboration with the ICAMS researchers we will be able to put improved materials on the market even faster and fulfill customer requirements even more accurately.