Trade press, 2025-03-25, 08:30 am

thyssenkrupp Steel and RWTH Aachen present CO2-reduced powercore® traction NGO 025-125Y420 in the rotor technology demonstrator at Coiltech 2025

- Innovative product: The CO2-reduced bluemint® high-performance electrical steel powercore® traction NGO 025-125Y420 by thyssenkrupp Steel is characterized by a very low remagnetization loss and high mechanical strength.

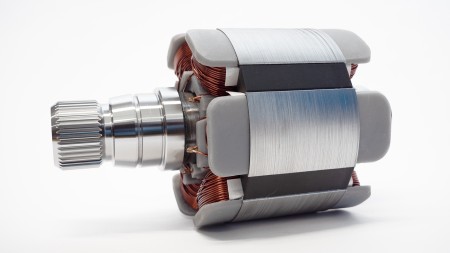

- Rotor technology demonstrator: In collaboration with the 'Production Engineering of E-Mobility Components' (PEM) Chair at RWTH Aachen University and other industrial partners, NGO 025-125Y420 was integrated into an innovative rotor technology demonstrator.

- Presentation at Coiltech 2025: The demonstrator will be presented at the Coiltech trade fair in Augsburg from March 26 to 27, 2025 at the PEM booth in Hall 5-D30; visitors will find thyssenkrupp Steel in Hall 1, Booth E14.

Duisburg, Germany, March 24, 2025 – thyssenkrupp Steel presents the CO2-reduced bluemint® high-performance electrical steel – powercore® traction NGO 025-125Y420 – which is characterized by very low core loss and high mechanical strength for use in modern traction motors. With these values, the new grade is one of the leading electrical steel grades produced in Europe and is now available for high-volume series production. As CO2-reduced bluemint® steel, the grade has a reduced CO2 footprint of around 13%, making it the ideal material for sustainable electromobility.

Remagnetization loss is a crucial material property: in simple terms, the value expresses how much energy is lost on the way from the battery to the power transmission of a vehicle due to the electrical steel used. The lower the loss of magnetization, the higher the efficiency of a traction motor. The electric car can then drive more kilometers on one battery charge or the battery capacity can be reduced while maintaining the same range. This reduces the weight of the battery and therefore also of the vehicle - and as a result, the car manufacturer's production costs are also reduced. With the new grade powercore® traction NGO 025-125Y420, thyssenkrupp Steel recently brought a material just 0.25 millimeters thick to series production that sets new standards in terms of performance. This high performance electrical steel is characterized by a very low remagnetization loss of a maximum of 12.5 W/kg (at 400 Hz and 1 T) and a high mechanical yield strength (Rp0.2) of at least 420 MPa.

RWTH Aachen uses NGO 025-125Y420 in research project

The innovative material by thyssenkrupp Steel was integrated into a new type of rotor technology demonstrator, which was developed and built as part of a consortium study by the “Production Engineering of E-Mobility Components” (PEM) Chair at RWTH Aachen University and other partners from industry. The rotor demonstrator impressively shows how sustainable materials and innovative production processes can increase the efficiency of electric motors.

David Pieronek, Product Manager for Non-Grain Oriented Electrical Steel at thyssenkrupp Steel: “Our powercore® traction NGO 025-125Y420 is an outstanding example of thyssenkrupp Steel's innovative strength. Our aim is to develop innovative solutions for e-mobility in close cooperation with leading research institutions and industrial partners and to bring them to series production. The rotor technology demonstrator is an excellent example of the successful implementation of this approach.”

NGO 025-125Y420 and rotor technology demonstrator at Coiltech in Augsburg

The demonstrator will be presented at the PEM booth in Hall 5-D30 at the Coiltech trade fair in Augsburg from March 26 to 27, 2025. The steel manufacturer's experts are also looking forward to welcoming visitors to the thyssenkrupp booth E14 in Hall 1. The Coiltech trade fair is one of the leading events for the electromobility industry and offers an ideal platform to find out about the latest developments and trends.

Visitors to the trade fair will also receive information on the demonstrator and the product NGO 025-125Y420 in the following presentations:

26.03.2025,

11:00 a.m., Hall 2: David Pieronek, thyssenkrupp Steel – NGO electrical steel solutions for advanced traction motors and sustainable E-mobility

02:00 p.m., Hall 5: RWTH Aachen – Innovations in rotor prototyping and manufacturing

The innovative rotor technology demonstrator was developed as part of the “Transformation Hub Scale-up E-Drive” project funded by the German Federal Ministry for Economic Affairs and Climate Protection (BMWK). The aim of the project is to validate various material and process-related innovations in an application context and demonstrate them to a wide audience.

Further presentations held by thyssenkrupp Steel

26.03.2025

11:50 a.m., Hall 2: Mustafa-Seckin Aydin, thyssenkrupp Electrical Steel – GOES for higher efficiency, more torque and reduced CO2 footprint in axial flux motors

3:50 p.m., Hall 3: Marcel Hilgers, thyssenkrupp Electrical Steel – Steel sector - The need for collaborative approaches: securing a resilient and sustainable supply chain for transformers

27.03.2025

2:30 p.m., Hall 3: Rüdiger Koshorst, thyssenkrupp Electrical Steel – GOES devolpment of thyssenkrupp electrical steel facing new challenges for further improvement on transformers efficiency