More information

precidur® precision strip from Precision Steel in Hohenlimburg has the tightest thickness and profile tolerances available in widths of up to 720mm and thicknesses from 1.5mm to 16mm.

-

Download precidur® product range

Precision strip – the hot-rolled steel strip with tightest tolerances

Thickness tolerances

| Strip thickness [mm] |

Standard tolerances [mm] |

Special tolerances [mm] |

|---|---|---|

| 1.5 – 2.54 | ± 0.04 | ± 0.03 |

| 2.55 – 4.03 | ± 0.04 | ± 0.035 |

| 4.04 – 6.03 | ± 0.05 | ± 0.04 |

| 6.04 – 8.03 | ± 0.055 | ± 0.045 |

| 8.04 – 9.03 | ± 0.06 | ± 0.05 |

| 9.04 – 11.03 | ± 0.07 | ± 0.055 |

| 11.04 – 14.03 | ± 0.08 | ± 0.06 |

| 14.04 – 16.00 | ± 0.10 | ± 0.07 |

precidur®: strong performance for more customer satisfaction

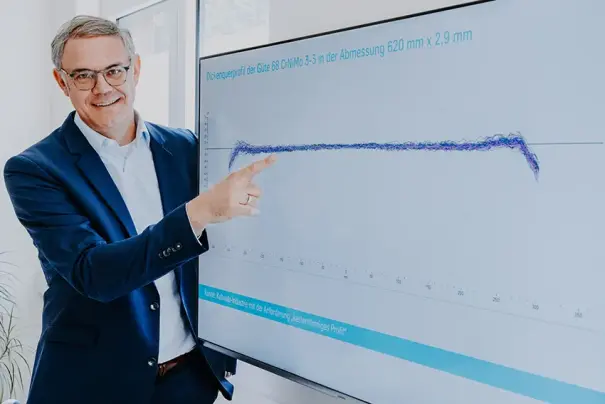

As Technical Manager, Dr. Christoph Evers is responsible for the precision strip mill at thyssenkrupp Hohenlimburg, which has recently carried out a number of very successful projects on the subject of strip geometry. In the interview, he reveals what matters to customers today.

"Even higher precision and more resistant to wear" are requirements we hear from customers every day. In addition, the profile requirements are becoming more multi-faceted: i.e. from slightly to strongly cambered, to a box-shaped thickness cross-section. For example, a well-known manufacturer in the cold rolling industry approached us for a project involving the production of rotationally symmetrical components from longitudinally split cold rolling strip. The profile trace achieved in this case proves the performance of the precision strip mill – innovative precidur® with box profile. The big challenge is to manufacture in a reliable process within these tight tolerances, not only in trials, but on a 24/7 basis.

Targeted modernizations were necessary at various points to achieve this enhanced performance – Where exactly did you start?

The technological controls, and here in particular the profile and strip flatness control, are continuously being further developed. Specifically, the profile control was expanded to include additional backup points in order to display a profile contour in the controller and thus to be able to implement customer requirements even better. To improve and validate the roll gap setting, a profile measuring device was installed behind the intermediate train, so that we now know the profile of the transfer bar. With the new combination grinding machine, we are able to grind the profile of the backup and work rolls to tighter tolerances, especially in the roll barrel edge area, which has further improved the predictability of the actual roll gap. With the upgrading of the intermediate train, we can ultimately also enter the finishing mill faster and hotter, and allow the material to flow better. The increase in rolling force combined with two new drives and a reinforced gearbox make the two interstands equally suitable for meeting the requirements of “even thinner and stronger”.

What distinguishes the approach of your specialist department as a "problem solver" for customers?

We are very close to customers, and always ready to talk and develop the specific solution together with them. Our technically very experienced customer service with high material competence is known for this. As a team, we then jointly translate these requirements for the processes at the precision strip mill. The customer is closely involved in this process and follows the individual test steps at close quarters. We look forward to hearing from you!

Contact:

Dr. Christoph Evers, thyssenkrupp Hohenlimburg, [email protected]

Further information

Detailed information on our products can be found in our product information. Individual material solutions or product concepts are of course part of our offer. Please contact us.precidur® product flyer for download

PDF English | 506 KB

PDF English | 379 KB

PDF English | 343 KB