Daily press, 2023-02-06, 08:30 am

50 years of the "Schwelgern 1" blast furnace: thyssenkrupp Steel's "black giant" in Duisburg celebrates its birthday

- It has been operating for 50 years, but is still one of the most modern blast furnaces: "Schwelgern 1" in Duisburg, one of the largest blast furnaces in Europe

- With a hearth diameter of 14 meters and a capacity of 4,200 cubic meters, blast furnace 1 set new standards in 1972 in terms of size and performance.

- After its relining in 2021, the "black giant" is back at the cutting edge and will be on its sixth furnace campaign.

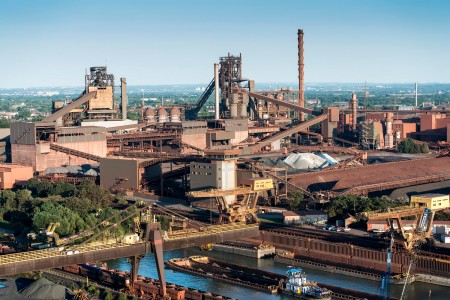

It was the largest of its kind in the western world when it embarked on its first "campaign" 50 years ago: the "Schwelgern 1" blast furnace in Duisburg was ceremonially inaugurated by the then August-Thyssen Hütte on February 6, 1973. The Thyssen flag fluttered at the top on this February day, and more than 500 invited guests from business and politics marveled at the "black giant" which, with a capacity of 10,000 metric tons of hot metal per day, remains one of the largest blast furnaces in the world today and, with its 110-meter-high silhouette, shapes the skyline of Duisburg-Marxloh.

Germany's Chancellor was Willy Brandt, it was the year of the Watergate affair and the first oil shock when "Schwelgern 1" started its work. Covering an area of 25 soccer fields, the large blast furnace with a hearth diameter of 14 meters and a capacity of 4,200 cubic meters set new standards in terms of size and performance. More than 70,000 cubic meters of concrete and 38,000 metric tons of steel were used in building the blast furnace – almost as much as would have been needed for four bridges over the Rhine. In operation, the plant requires around 20,000 metric tons of ore, sinter, coke and coal every day – the contents of 20 freight trains with the same number of wagons.

Environmental protection as the greatest challenge

Even back then, special attention was paid to environmental protection. A team comprising more than 50 chemists and designers worked with the goal of achieving a "blue sky over Hamborn". Despite the environmental protection facilities accounting for a good 15 percent of the total construction costs at the time, for example for gas cleaning, water treatment and noise abatement, "Schwelgern 1" initially caused resentment among local residents: They only rarely saw a "blue sky over Hamborn". Instead, just days after the furnace was blown in for the first time, they complained about noise, dust and bad smells – problems that Thyssen got to grips with by subsequent modifications, however. Since then, massive investments have repeatedly been made towards improving environmental protection, especially in dust removal. And since 2020, the colossus has also been emitting less carbon dioxide than before thanks to an innovative process in which additional oxygen is injected.

In 1973, no one could have imagined that the "Schwelgern 1" blast furnace would run for more than 50 years. Nevertheless, the steel mill director at the time, Dr. Hermann Brandi, demonstrated amazing foresight at the ceremonial inauguration. "As iron and steel makers, we are counting on the blast furnace and the basic oxygen steel converter as a cost-effective production route for decades to come – even if, at the same time, favorable opportunities are opening up for the direct reduction process under certain circumstances," he emphasized in his speech at the opening ceremony. As predicted by Brandi, the Schwelgern 1 blast furnace provided reliable service for five decades. Now, 50 years later, thyssenkrupp Steel Europe is setting out into a new, environmentally friendly era of steel production – and is relying on the direct reduction process mentioned by Brandi.

Technology at the cutting edge after the overhaul

Despite the imminent move away from blast furnace technology, "Schwelgern 1" was once again brought back to the state of the art in 2021 for the transitional period. After a three-month shutdown and the investment of a sum running into the mid-double-digit millions, thyssenkrupp Steel launched the steel colossus onto its sixth and thus probably final "furnace campaign" in October 2021 with a hearty "Glückauf" – a special ceremony to wish good luck for the furnace operations. As part of the transformation to carbon-neutral steelmaking, the coal-fired blast furnaces will be replaced by direct reduction plants operating with hydrogen. thyssenkrupp Steel plans to place the order for a first plant shortly. Then the "black giant" will also take its well-deserved "retirement" after its last campaign.