Trade press, 2014-01-29, 01:29 pm

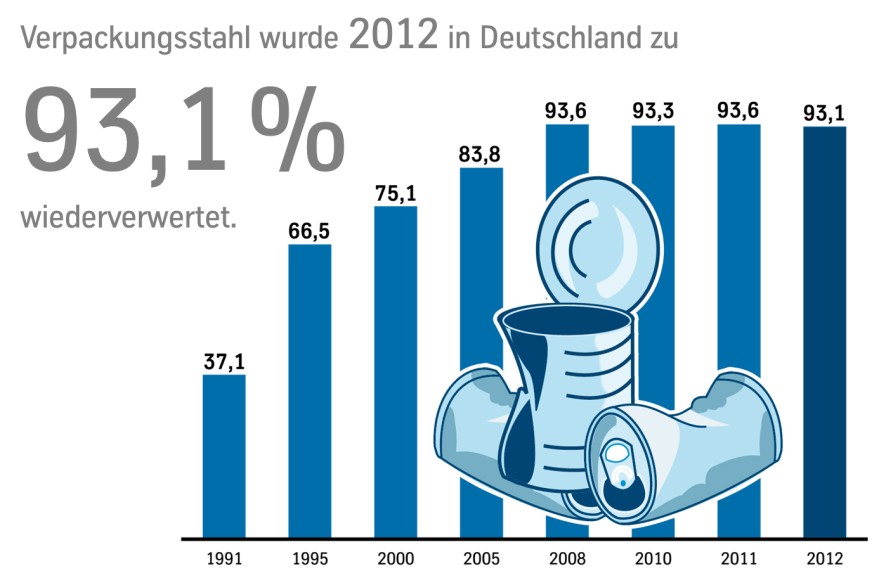

Tinplate recycling in Germany 2012 over 93 percent again

With a material recycling rate of 93.1% of the material consumed, tinplate maintained its top position among packaging materials in Germany once again in 2012. The tinplate figure published annually by the Gesellschaft für Verpackungsmarktforschung (Society for Packaging Research), which was over 90% for the seventh time in a row, has stabilized with values around 93%. At the same time, after a temporary decline in the quantity of steel packaging sold, steel packaging purchases increased by approximately 2% to 501,500 tonnes. At 95.6%, the recycling rate for tinplate packaging from household consumption is higher than the overall rate and proves the great efficiency of household disposal systems.

For the first time since the definition of the five-level waste hierarchy by the Recycling and Waste Management Act of 2012, the current statistics of the "recycling balance sheet for packaging" will break down material and energy reclamation values separately. It will therefore be even clearer which packaging materials actually fit the common definition of "recycling." Steel is a "permanent material," one that retains its properties undiminished even after many reuses. The recycling balance sheet reflects the material property of tinplate packaging as being 100% in harmony with overall recycling and material recycling. Nothing is lost or declines in quality, nothing is incinerated or pollutes rivers and seas.

The enormous efficiency of the recycling of packaging steel makes a significant contribution to preserving the environment. Each tonne of steel recycled eliminates the costly creation of primary steel. Therefore to an ever-increasing extent, each newly-manufactured steel product contains a percentage of recycled steel. Recycled steel requires neither newly-mined iron ore nor the additives required for smelting, and especially not the huge amount of energy that is needed to manufacture raw steel.

"Despite the pleasingly high return rate, we have observed with concern that an increasing share of steel packaging from household use is being diverted into 'gray zones' and removed from the dual systems," notes Dr. Ulrich Roeske, Chair of Germany's only tinplate manufacturer, ThyssenKrupp Rasselstein. "In particular, return systems in retail and industry solutions for large consumers invite manipulation and cheating. If the real concern is product responsibility, it would be better to eliminate these possibilities. Consumers would be the big winners," continues Roeske.

With the world's largest production location, ThyssenKrupp Rasselstein is one of the most important suppliers of packaging steel to Germany and Europe. The company, based in Andernach, assumes responsibility for its products by ensuring through its contracts with two companies that tinplate from commercial and household packaging is returned to the recoverable substance cycle. For 20 years, ThyssenKrupp Rasselstein has worked with the KBS Kreislaufsystem Blechverpackungen Stahl GmbH, a non-profit company operated by ThyssenKrupp Rasselstein, the Verband Metallverpackungen e.V. and the Bundesverband Deutscher Stahlrecycling- und Entsorgungsunternehmen e.V., to collect, prepare, and reuse industrial tinplate packaging. For 10 years, the ThyssenKrupp Rasselstein subsidiary Deutsche Gesellschaft für Weißblechrecycling mbH has been a marketer of tinplate scrap from the disposal of household consumption.