Trade press, Daily press, 2017-11-30, 05:00 pm

Study confirms: tinplate packaging offers a high degree of recyclability

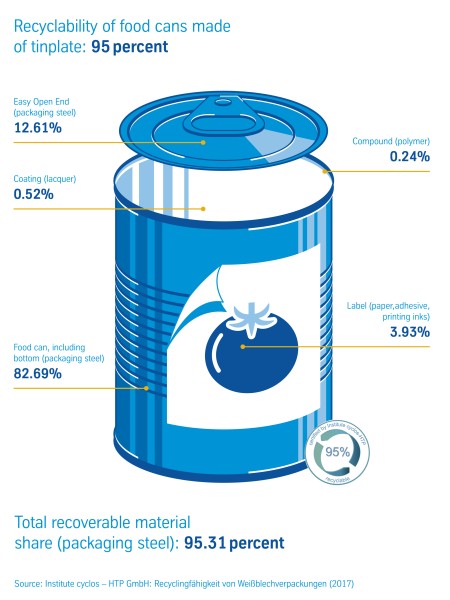

Top results for packaging steel: The degree of recyclability of cans is almost identical to the tinplate content of their packaging. A three-piece food can with a ring pull end, for instance, has a high degree of recyclability of 95 percent. Essentially, this small difference to the 100 percent mark has to do with labelling and compound. This is what a study by scientific institute cyclos-HTP on behalf of thyssenkrupp Rasselstein GmbH has found while analyzing commonly available tinplate packaging.

“The degree of recyclability of a product describes its gradual material suitability to contribute to the closing of material cycles within the framework of established collection, utilisation, and recovery structures. It is extremely rare for a product to offer a degree of recyclability of 100 percent; a paper sleeve, for instance, while important for displaying consumer information, lowers its degree of recyclability,” Dr. Joachim Christiani from the Institute cyclos-HTP explains.

Christian Pürschel, in charge of communications and market development for Germany’s sole manufacturer of packaging steel, highlights this further: “This study has confirmed, once again, that steel packaging is an ecological top performer. Once packaging has reached the end of its useful life, the steel from which it is manufactured can be recycled and used to make new products, thus closing the material loop.” thyssenkrupp Rasselstein GmbH is fully committed to closing the cycle of reusable materials, not least thanks to its subsidiary, the Deutsche Gesellschaft für Weißblech Recycling (DWR), which ensures that tinplate packaging is returned to the steel manufacturing process in a professional and targeted manner.

The results of the study will grow even more in importance when the new German Packaging Act comes into force on January 1, 2019. When producing packaging that is subject to dual systems participation and in the context of participation fee assessment, return and recycling systems will then be obliged to provide incentives to encourage the use of materials that can be recycled as much as possible. This is where the degree of recyclability of a material comes into play. Going forward, the newly established Zentrale Stelle (Central Packaging Register), in collaboration with Germany’s Federal Environment Agency, is going to define minimum standards for the degree of recyclability of packaging.

“This is a clear advantage for tinplate packaging, which stands out with its degree of recyclability of almost 100 percent,” Pürschel explains. “Steel packaging fulfils the physical and material prerequisites whereby it can turn almost entirely into a secondary product comparable to its brand-new equivalent after use. This cycle can be repeated as often as required, without the material properties changing.”

Contact:

thyssenkrupp Rasselstein GmbH

Volker Lauterjung

Head of Communications

Phone: +49 2632 3097 - 2875

[email protected]

www.thyssenkrupp-steel.com