Trade press, 2015-11-10, 02:24 pm

Tinplate Most-Recycled Packaging Material in Germany Once Again in 2014

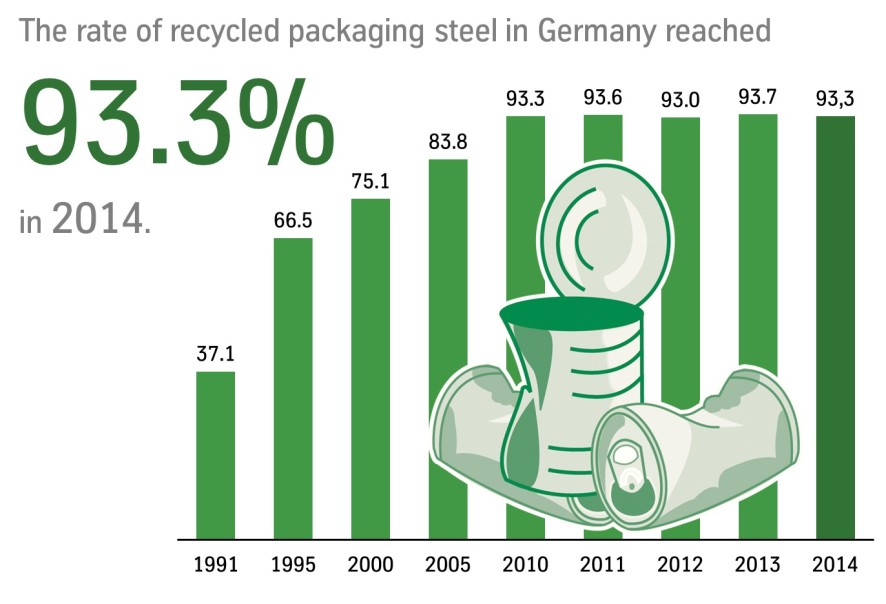

With a recycling quota of 93.3% of the Tinplate packaging consumed in Germany, packaging steel has retained its top position once again in 2014. For the large share of packaging from private consumption, the quota for material recycling is still higher: it was 95.9%. The Gesellschaft für Verpackungsmarktforschung (GVM) [Association for Packaging Market Research] has now published the figures for 2014 in its annual "Recycling Balance Sheet for Packaging."

These values confirm the values that have been over 93% since 2010 and thus the highest recycling level for packaging materials ever. "The complete correspondence between overall recycling and material recycling thus demonstrates impressively that in the case of steel packaging, recycling means actual and complete reuse. As a "permanent material," steel can be subjected to this process as often as desired without having its substance or properties deteriorate," explains Dr. Ulrich Roeske, Chair of the Board of ThyssenKrupp Rasselstein, the only manufacturer of packaging steel in Germany.

The quotas determined are slightly below the values for the previous year, when overall recycling of 93.7% and recycling from private end consumption of 96.6% were measured. The slightly declining overall consumption quantity of 487,700 tonnes relies, according to the estimation of the GVM, among other things on the declining weight of cans and beverage cans, as well as Tinplate closures such as crown seals. ThyssenKrupp Rasselstein engages itself especially intensively in the development of ever-thinner packaging steel products, which with at least the same properties enable higher packaging performance per material quantity used.

"Together with the ecological advantages of steel packaging, such as the long-term energy-free storage life of food, the high recycling rate, to which we in Germany contribute significantly through our own recovery activities, makes an important contribution to sustainability," emphasizes Roeske. "We also emphasize this against the background of an incomprehensibly high loss of food, which rots in many part of the world before it can reach consumers. Packaging steel allows safe protection of food against spoilage and means that it can be kept for years without preservatives."

Thanks to the loss-free reusability of used steel, recycled materials replace primary resources such as iron ore, bituminous coal, and additives that would otherwise be required in order to manufacture the same quantity. Any newly-produced steel thus contains an increasingly high share of former steel products. Ulrich Roeske: "We at ThyssenKrupp Rasselstein, together with the Deutsche Gesellschaft für Weißblechreycling (DWR) [German Association for Tinplate Recycling] and participation in the non-profit company Kreislaufsystem Blechverpackungen Stahl GmbH (KBS) [Recycling System for Sheet Metal Packaging Steel GmbH], have ourselves been contributing to the marketing and pinpointed return of used steel packaging to the production process."

ThyssenKrupp Rasselstein, a subsidiary of ThyssenKrupp Steel Europe, produces approximately 1.5 million tonnes of packaging steel in Andernach, in the German state of Rhineland Palatinate. In this largest location of its type worldwide, ThyssenKrupp rolls steel to an extremely thin 0.100 mm thickness and finishes the surface with tin or chrome. Nearly all of the company's output is shipped to packaging producers around the world. In addition to cans for food and pet food, packaging steel is used for beverage and aerosol cans, containers for chemical and technical goods, as well as crown seals and twist-off tops. ThyssenKrupp employs approximately 2400 people in Andernach.