Packaging Steel

Premium quality and outstanding service

At the world’s largest production site for packaging steel, located in Andernach, thyssenkrupp produces tin coated or electrolytic chromium coated steel in thicknesses of 0.100 to 0.499mm – either with or without organic coatings (lacquer, polymer). As one of Europe’s biggest packaging steel manufacturers, we serve around 400 customers in 80 countries.

rasselstein® – Material Matters

thyssenkrupp produces the packaging steel of the future – efficient, process optimized and sustainable. rasselstein® packaging steel stands for material grades in premium quality which are continuously further developed in close cooperation with our customers.

Further topics

Packaging Steel in images

The production halls of the world's largest tinplate manufacturer extend along the bank of the Rhine, southeast of Andernach and across the river from Neuwied.

The production halls of the world's largest tinplate manufacturer extend along the bank of the Rhine, southeast of Andernach and across the river from Neuwied.

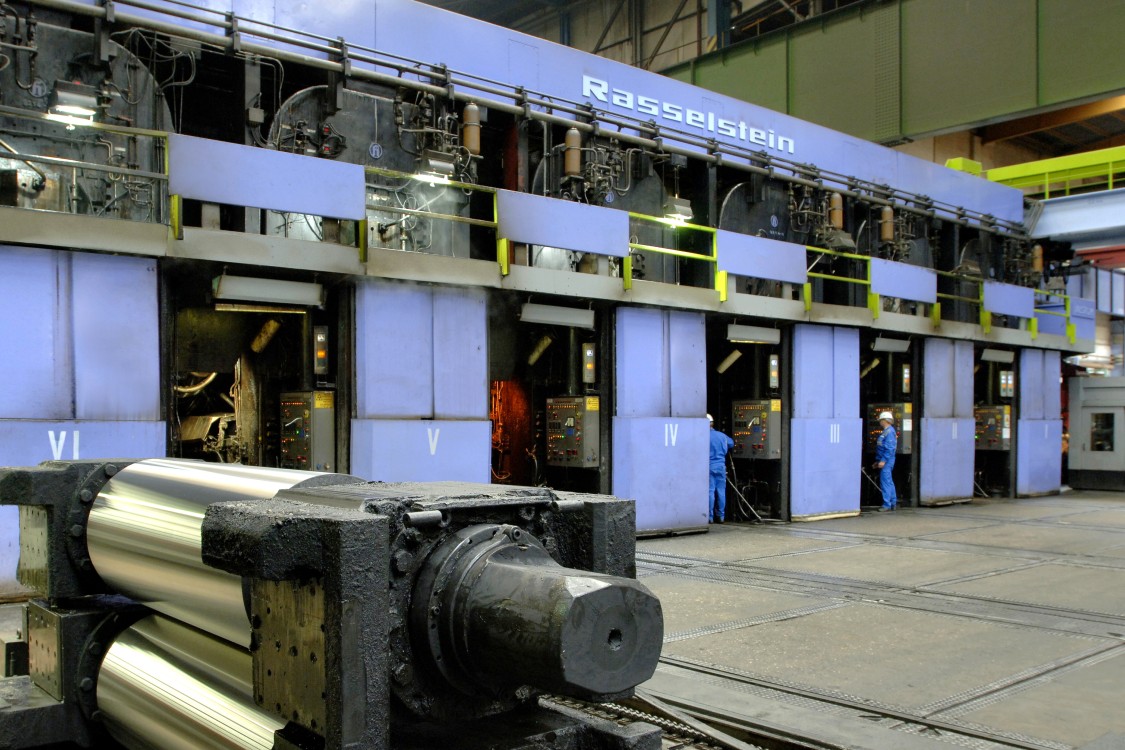

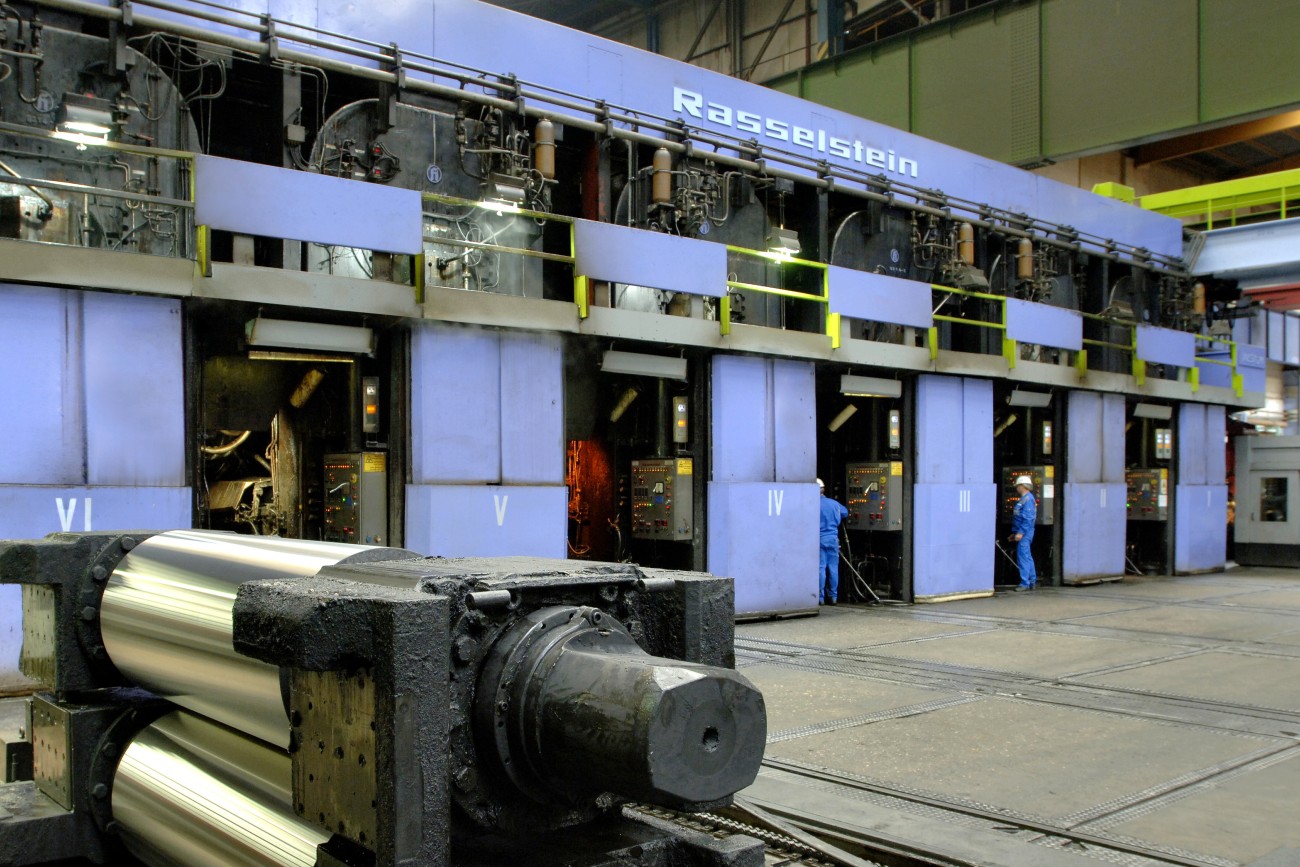

Flat steel is rolled in the six-stand strip mill which permits a reduction of thickness by more than 90%.

Flat steel is rolled in the six-stand strip mill which permits a reduction of thickness by more than 90%.

The cold-rolled steel strip is heated to up to 830° degrees Celsius for a short time in the annealing furnace in a continuous process. The structure of the steel destroyed during cold-rolling is restored.

The cold-rolled steel strip is heated to up to 830° degrees Celsius for a short time in the annealing furnace in a continuous process. The structure of the steel destroyed during cold-rolling is restored.

Tinplate gets its name and characteristic appearance by the extremely thin layer of tin or chrome electrolytically applied to the steel sheet.

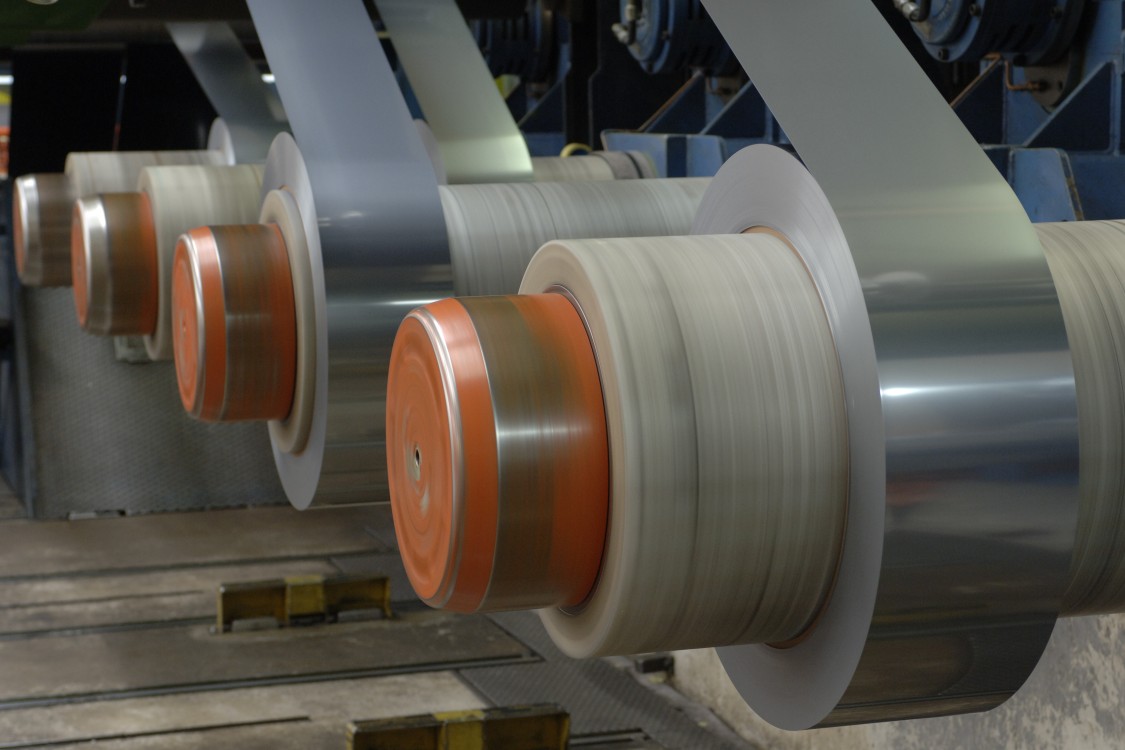

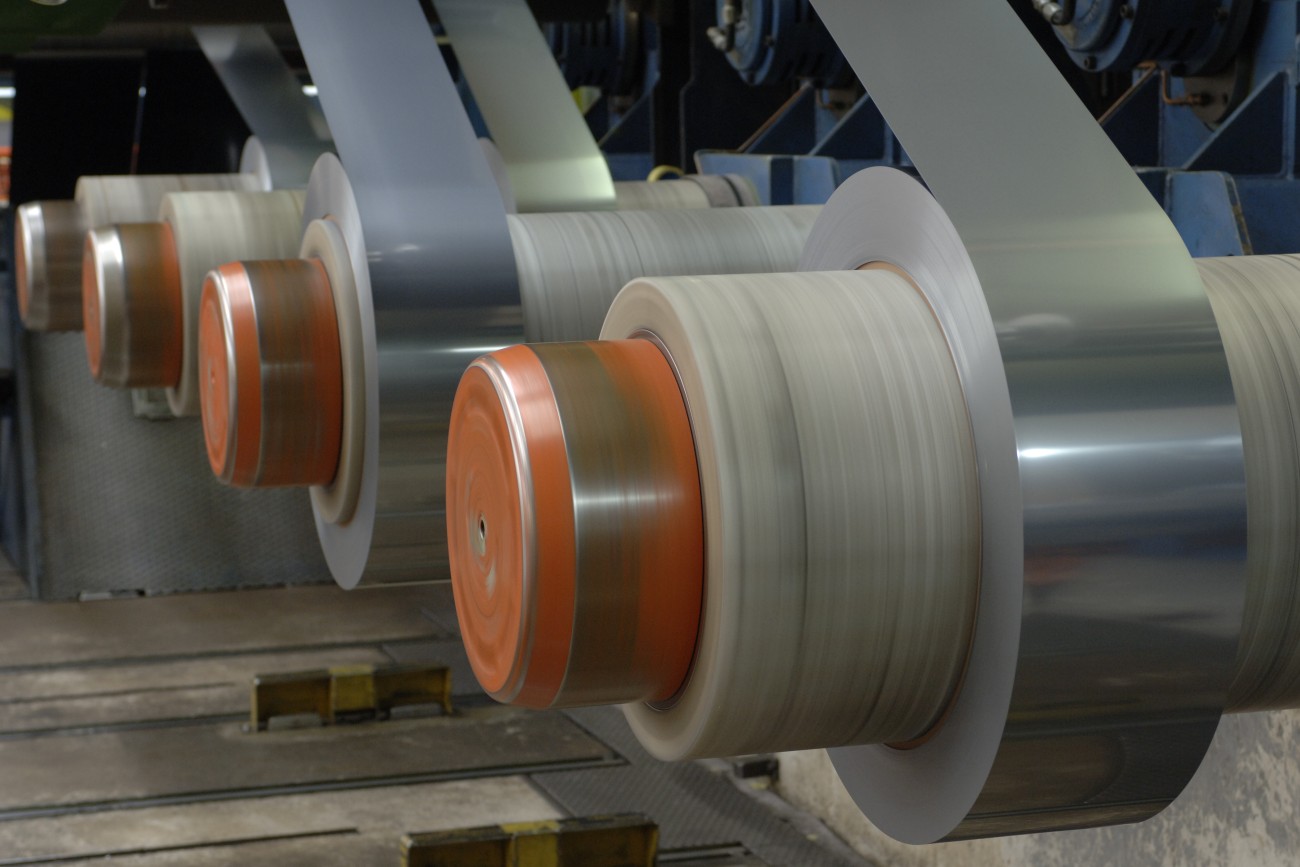

When a coil is processed, another one is already wound and prepared for processing so that the end of the first is welded together with the front edge of the following strip.

Tinplate strip can be lacquer-coated on one or both sides and/or laminated with plastic film according to need.

The computer-controlled complex processes of tinplate production are supervised by plant operators at clearly arranged control units.

The computer-controlled complex processes of tinplate production are supervised by plant operators at clearly arranged control units.

The computer-controlled complex processes of tinplate production are supervised by plant operators at clearly arranged control units.

Despite permanent quality surveillance by measuring and inspection equipment - here on a tinning line - the trained eye of an experienced employee is indispensable.

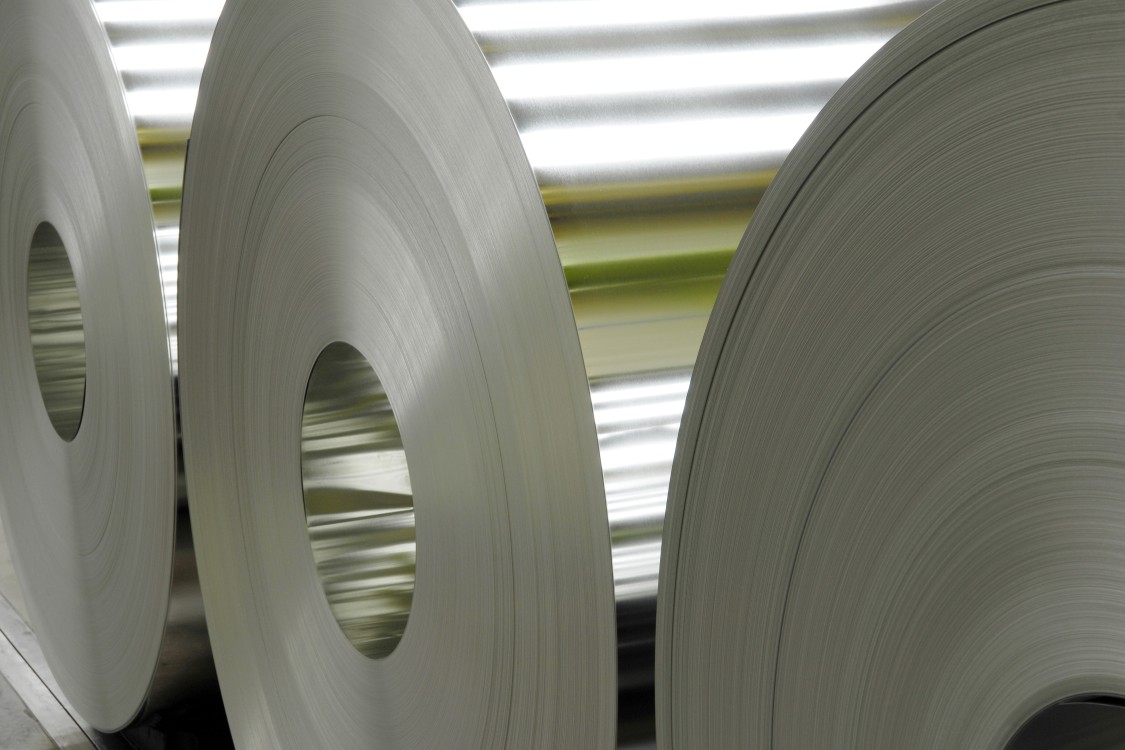

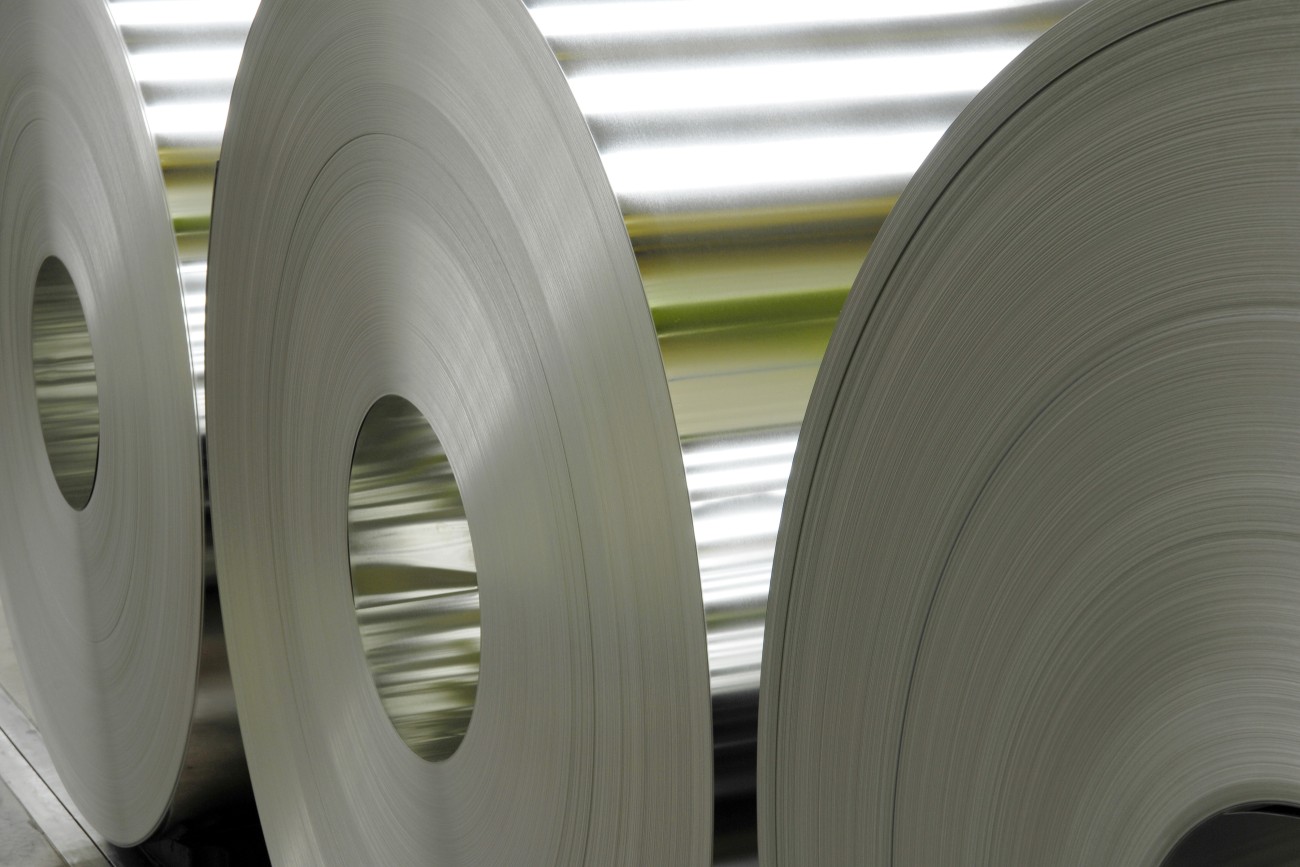

The steel strip passes through the complete process as a coil. A large portion of the deliveries also goes to customers in the form of coils. The surface of the tinplate is governed by temper-rolling and the thickness of the tin layer according to customer requirements.

Tinplate can not only be delivered coated with organic surfaces but can also be divided into different layouts according to customer specifications. Slitting lines separate the sheets lengthways into narrow strips.

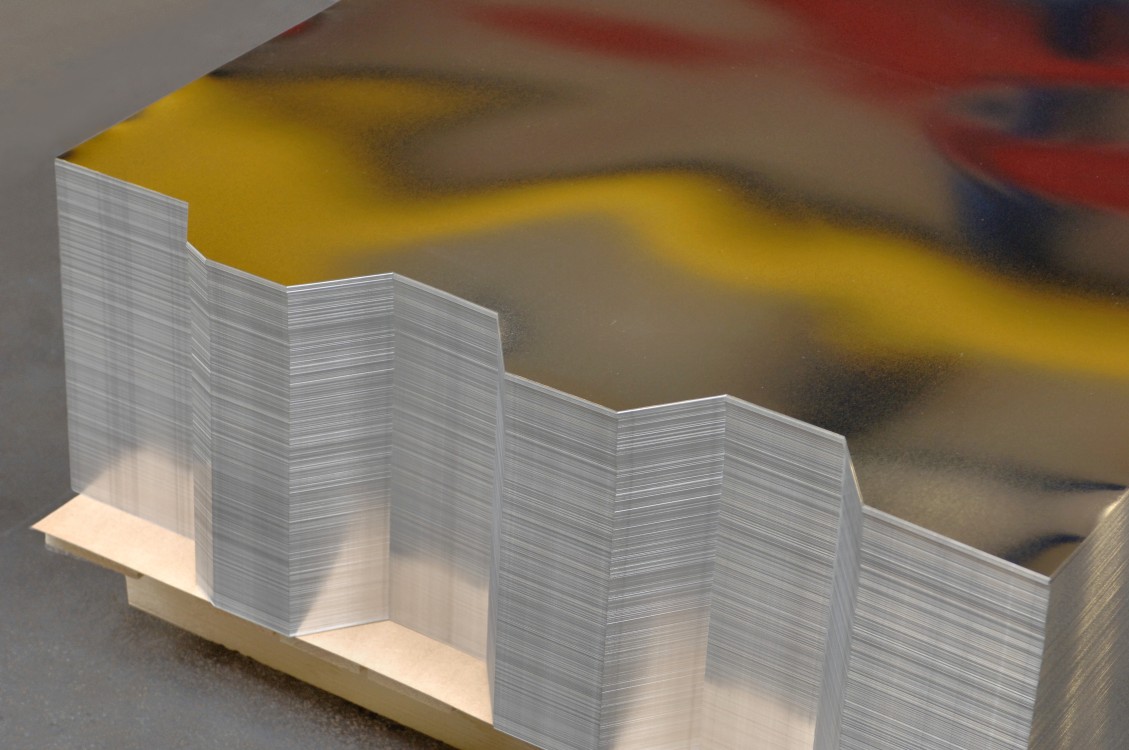

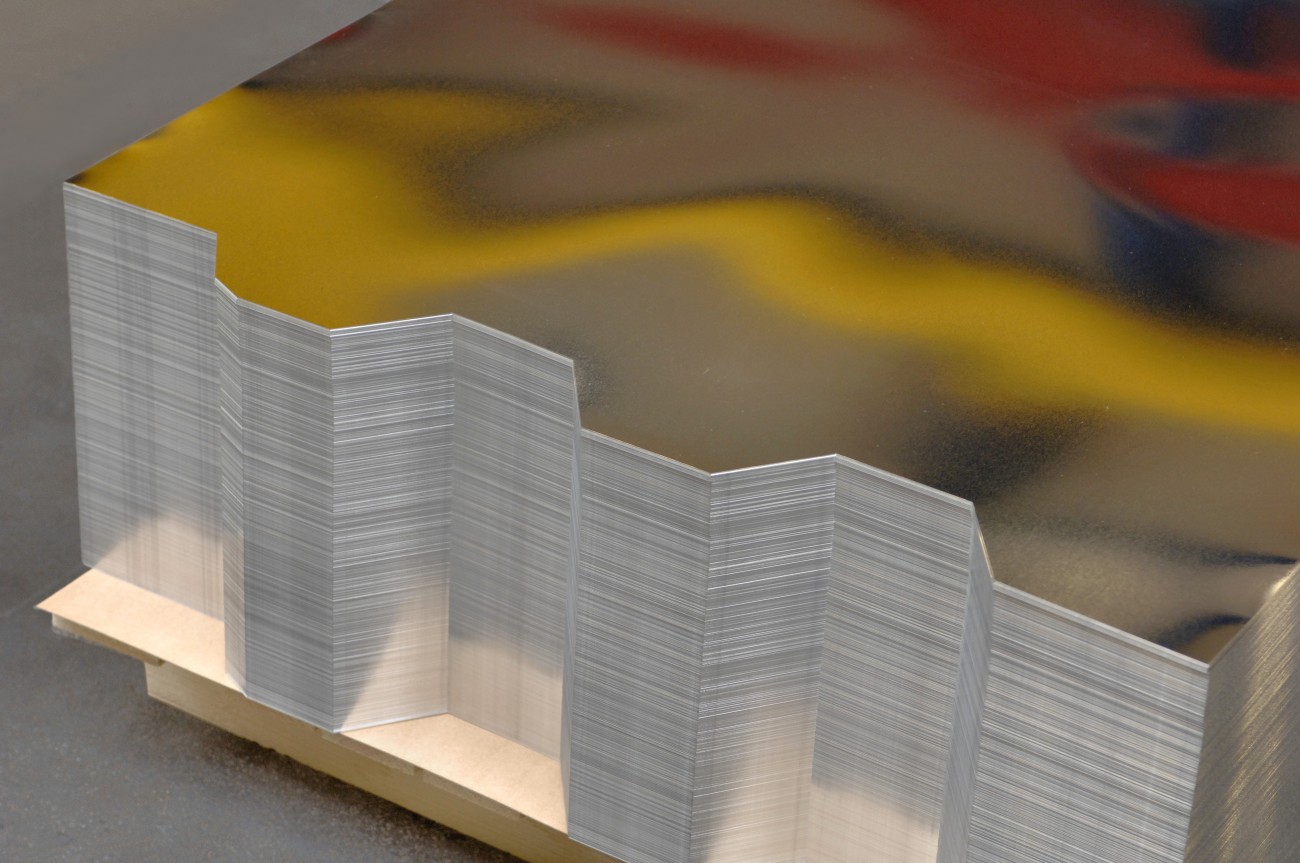

Sheets with straight edges or - shown here - being customized with a pattern by cross cutting the strip on the cutting line.

Coils are ready to be packed for transportation. Depending on the destination and means of transportation, different packing forms are required to protect the material from damage in transit and environmental conditions.

In our two storage facilities for finished goods - one used exclusively for coils - the products are prepared for delivery according to the customer’s transportation requirements.

Scrap metal arising from the production process, such as trimmings from steel strip before coating, is portioned as a high-quality secondary raw material for renewed use in the steel mill.

Modern sorting technology enables a high sorting purity, which makes used tinplate a valuable ingredient for steelmaking. An electromagnet crane transports tinplate blocks to the steel mill.

A pouring container with a precisely calculated scrap metal mixture before the filling of the converter.

A pouring container with a precisely calculated scrap metal mixture before the filling of the converter.

Company policy