The new furnace has been working more efficiently, and therefore with greater savings, since the comprehensive modernization measures. Moreover, the total complement of four furnaces is also equipped with an optimized safety control system.

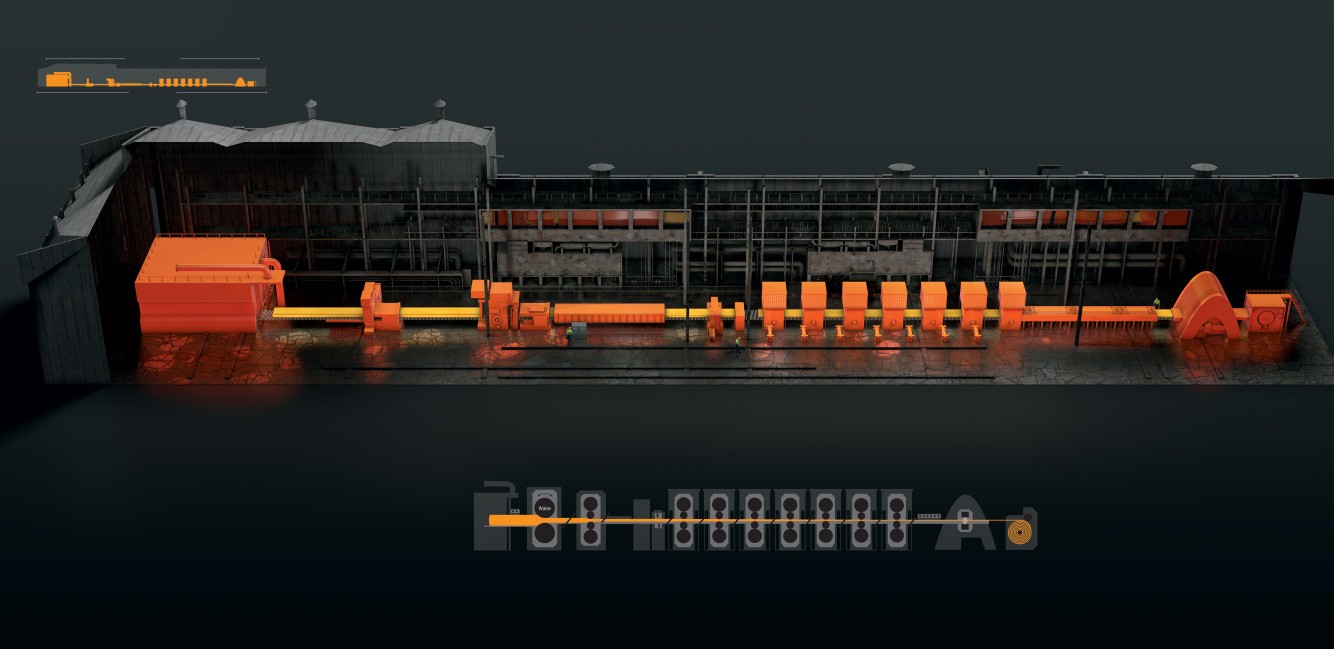

Every year the hot strip mill processes about three million tons of steel in Duisburg. The core of the operation is a newly modernized finishing train.

The descaling plant cleanses the steel blanks (slabs) of oxidized carbon at high pressure (115 bar). This guarantees high levels of purity for the steel.

The edger sizes the steel blank to the correct width. The same housing also contains a rolling mill with two rollers.

Two large back-up rollers drive two smaller drive two smaller working rollers, making it possible to exert even more pressure on the slab. The measuring system connected at this point checks the slab for temperature, thickness, width and surface quality.

One of the most innovative developments has been the roughed strip cooling system' recently. It is possible to develop new steel microstructures, because the processing temperature has a major impact on the subsequent properties of material.

Camera image and measurement reports are fed into the command center of Hot Strip Mill 1 in Duisburg. Here, modern software from Siemens carries out automatic corrections to the rolling and cooling processes, enabling strict tolerances in the micromillimeter range.

Since the edges cool down first, they have to be reheated a little to ensure that the slab maintains a constant processing temperature. This is achieved by the edge heater.

The cropping shear slice the rough edge off to make sure the slab has a straight end before it proceeds to the finishing train at a speed of around 15 meters a second.

Rolling gear that is seven times heavier is deployed in the finishing train, producing the desired steel sheet strenght using computer software. The rearmost roller is equipped with a further measuring system for control purposes.

It now rains pretty regularly in the cooling section, which has been converted into a modern laminar cooling facility, so that the drop in temperature can be exactly regulated. This makes it possible to produce even higher strenght steels than before.

This measurement cabinet (visually modeled on the Thyssen arch) inspects the surface and width of the steel sheet as it slides past. Sensors relay the condition of the coil to the technicians in the control unit while it's being wound.

Whatever gets 'uncoiled' tends to be in a bit of a mess. But a good coiling device knows how to wind steel sheet tidily. Watch out through: The sheet still hasn't quite cooled down. There's still enough heat left to fry an egg!

The slab - in other words, the steel blank - emerges from the furnace at a temperature of 1,000 degrees Celsius. After descaling, it moves on to two coarse rolling mills in order to thin out the slab as much as possible.

The seven rollers now operate at a capacity of 3,500 metric tons (previously only 2,800) after the modernization measures. The smaller working rollers are relieved every two hours. For the changeover the are pulled outward, and then ground smooth again.

A multitude of sensors now supports the fully automated process. For Hot Strip Mill 1, this means a tangible leap forward in quality. The new systems for regulating profile, contour and flatness enable particularly uniform and precise measurements to be made throughout the entire lenght and width of the hot wide strip.