Trade press, 2019-03-26, 10:20 am

Coil-coated flat steel of the pladur® brand has been popular for 60 years

The Americans send two monkeys into space, a Soviet rocket reaches the moon, and the first “Mini” rolls off the line. A spirit of optimism and innovation characterizes the lifestyle in 1959. During the same year, a new material causes a stir among architects and builders, an organic coated flat steel that opens up unimagined possibilities for the design of exterior facades and interior fittings. The innovations in this thyssenkrupp steel product family have fulfilled the highest standards of aesthetics, quality, formability, a wide range of colors and cost-effectiveness for 60 years.

Beginning of a success story

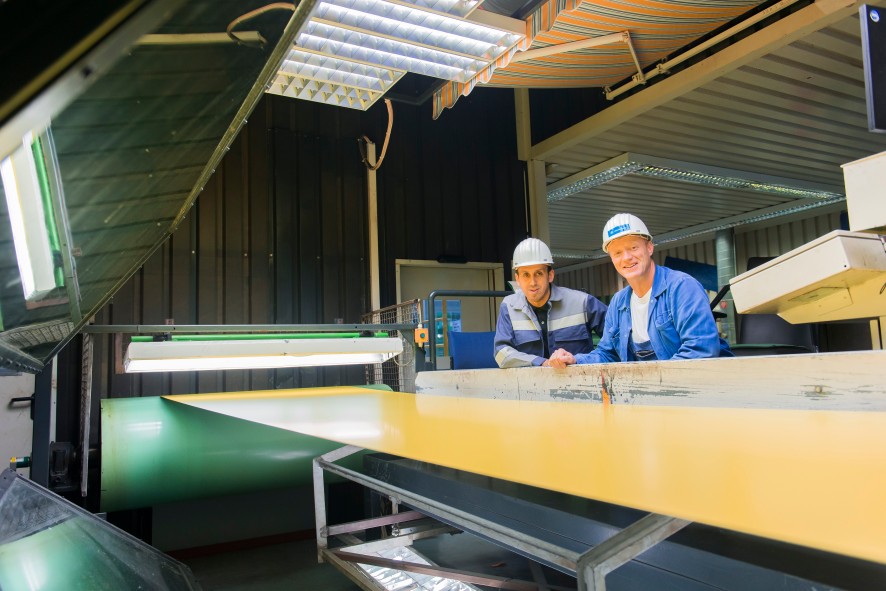

Several companies, now united under thyssenkrupp Steel Europe, launched Europe’s first wide-strip coil coating plant for the production of organic strip coated flat steel on May 26, 1959. And no one suspected yet that this is the beginning of a success story. The new material was presented to the general public at the International Plastics Trade Fair in Düsseldorf in October and impressed experts immediately. Because stability, good formability, and various surfaces with numerous color options make even unusual ideas possible. Today, pladur® products are produced on the coil coating lines in Kreuztal-Eichen, Kreuztal-Ferndorf, and Duisburg-Beeckerwerth.

Dashboard made of coil-coated flat steel

The wonderland of economic success enthusiastically embraced the increasing variety of products in the 1960s. Exterior façades of industrial and multi-story buildings, elevator partitions, gas pipes, deep-drawn parts for suitcases, and even the dashboard for the Ford 20M TS are now equipped with the coated flat steel. Its biggest breakthrough is its use as construction material and architects still like it today for the cladding of exterior façades, interior fittings, and roof structures. “Our coating systems, which we continue to develop for and with our customers, continue to offer new, attractive, and cost-effective design options. That has been the success story of pladur® for 60 years,” says Jörg Paffrath, CEO of the Industry business unit at thyssenkrupp Steel Europe.

Environmentally friendly manufacturing process – great variety

pladur® was used as the first coil-coated product and still has its place today not only in construction, but also in the garage door, household appliance and trailer industry. Over the past 60 years, thyssenkrupp Steel has continuously raised its standards in terms of material requirements and surface variety, since pladur® can be used for products with a decorative film in addition to painted products. Even façade and garage gate elements made of steel with the grain and feel of real wood are part of the almost unlimited portfolio. The steel manufacturer also sets high standards concerning the environmental friendliness in the manufacturing process. Chromium is dispensed with during the pre-treatment and heavy metal-containing pigments in the coating process. In addition, pladur® offers engineers, architects, and project developers enormous freedom of design. More than 8,000 shades are available in different coatings and numerous steel grades. “pladur® is our colored and functional finish coating on steel for premium manufacturers,” says Axel Pohl, Sales Director in the Industry business unit. Stability and good formability are among the key material properties.

Eye catcher in the Bauhaus year

In the current Bauhaus anniversary year, the color collection “Bauhaus style natural matt” is likely to be met with increased interest. The bold colors and pastel shades make the façades of high-quality multi-story and industrial buildings even today an aesthetic eye-catcher. With design solutions made of steel, even ideas from the Bauhaus school can be interpreted in a modern way.