Trade press, 2019-10-24, 12:50 pm

High-strength bainitic steels for the auto industry

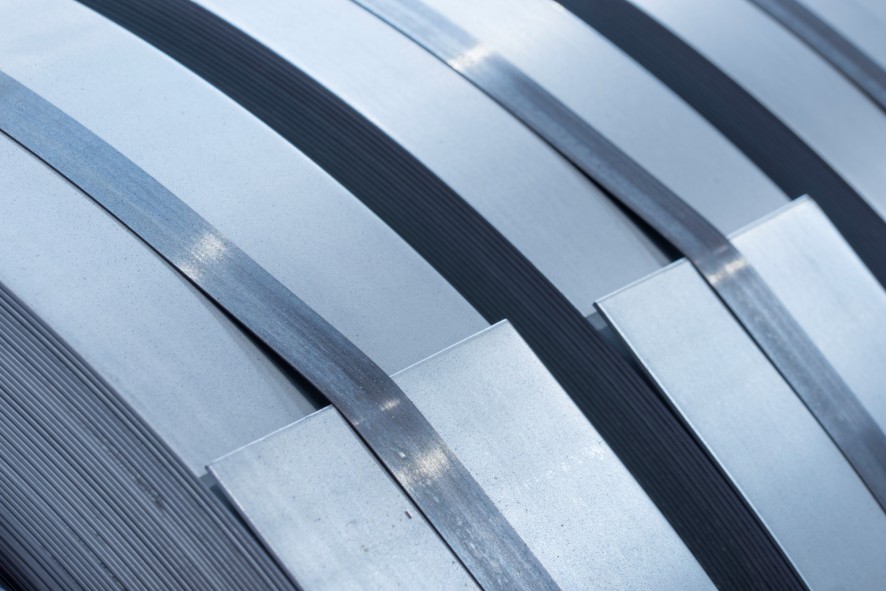

With newly developed precidur® hot-rolled grades from Hohenlimburg, thyssenkrupp Steel has added further high-performance steels to its portfolio of products for the auto industry. Alongside the established grades precidur® HBS 600 and precidur® HBS 800, the precision strip spectrum now also includes the new grades precidur® HBS 900, precidur® HBS 1000, and precidur® HBS 1000 HE, expanding the range of applications for high-strength steels in chassis components. “HE” designates steels with increased formability for punched or cut edges versus the standard grade.

The precidur® HBS grades are steels with a quasi-single-phase bainitic microstructure. These high-strength steels offer improved processing properties: they are highly suitable for critical forming operations due to their favorable yield-to-tensile ratio. With increased resistance to edge cracking and punching imperfections, they are optimized particularly for the forming of punched and cut edges.

As a result, precidur® HBS 900, precidur® HBS 1000 and precidur® HBS 1000 HE offer a new and innovative solution for complex chassis and structural parts with high strength and safety requirements. High tensile stresses along trimmed edges occur in these parts during and after forming as well as during subsequent use in the vehicle. In addition these new grades display very good weldability, an essential requirement in auto construction, as well as increased hole expansion capacity. These three new solutions thus provide a valuable addition to the range of high-strength steels.