Daily press, 2019-04-16, 05:30 pm

Hydrogen instead of coal. thyssenkrupp Steel launches pioneering project for climatefriendly steel production at its Duisburg site

- State government funds first test phase at Duisburg steel works

- Project is the first funding under the initiative IN4climate.NRW

- Project partner Air Liquide is supplying the hydrogen

Duisburg, 15th April. North Rhine Westphalia Economics and Digital Minister Prof. Dr. Andreas Pinkwart handed over a grant statement from the state on Monday in order to support the de-carbonization of production at the largest German steel manufacturer by using hydrogen. At the same time, the comprehensive transformation of the site towards climate-friendly steel production will be pursued further. thyssenkrupp Steel's long-term goal is to reduce the emissions of CO2 by production up to now by at least 80 percent by 2050. The project, which is about to begin, will be funded under the initiative IN4climate.NRW, which was recently launched by the state government. Economics and Digital Minister Prof. Dr. Andreas Pinkwart: “It is a great pleasure for me today to hand over the grant statement for the first project of the IN4climate.NRW initiative, with which we are taking an important step towards a climate-neutral industry. In order to achieve ambitious climate protection with a globally competitive industry in the future, there must be innovations in industrial and energy-intensive processes such as steel production. Land North Rhine-Westphalia would like to go along this transformation path together with industry and science. The pilot project shows that our IN4climate.NRW initiative is already bearing fruit. I am glad that we have thyssenkrupp Steel, Air Liquide Deutschland GmbH and BFI here as an innovative partner by our side.” Air Liquide, a world leader in industrial gases, is supplying the hydrogen needed for the project.

Hydrogen project: Another milestone on the way to climate-friendly steel production

thyssenkrupp is committed to the Paris climate protection goals. With the necessary conversion of its steel production the business is proceeding with an open mind towards technology and is using different, complementary approaches. For example, emissions in steel production can be converted into chemical products with the already successful Carbon2Chem project. Greenhouse gases are used as valuable raw materials in this way.

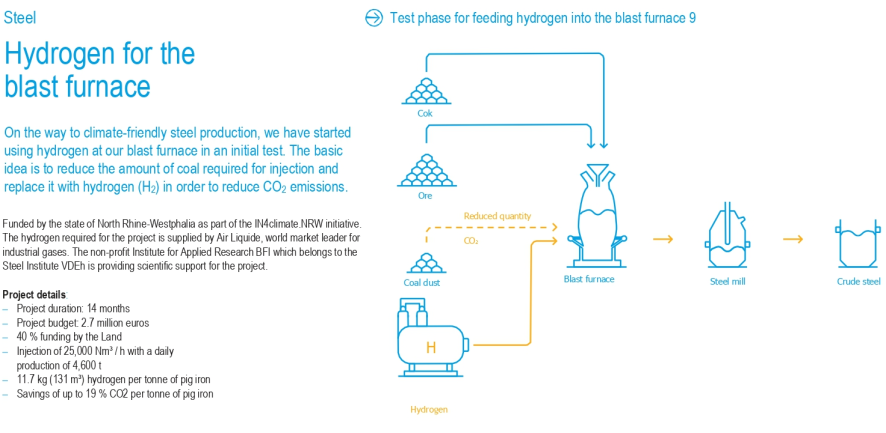

The hydrogen project at the blast furnace is pursuing another technology path: here the production of any harmful greenhouse gases at all is avoided. This is done by replacing some of the coal dust used as a reducing agent in the blast furnace by the injection of hydrogen. “With the use of hydrogen at our blast furnace 9, we continue to work consistently on the conversion of our production processes. Our goal is almost CO2-neutral steel production. This will be a long and costly process, and we will take another step today”, explains Arnd Köfler, Production Director of thyssenkrupp Steel Europe. “In the first months of this project, we will first test the use of hydrogen in one of 28 blow moulds in a blast furnace. This is an innovation and has not been implemented so far in the industry. We will analyse the results of this test phase precisely and then want to convert the entire blast furnace in this way in a second project phase,” adds Köfler. “Theoretically, a savings potential of around 20 percent CO2 at this point in the production process is possible. We are very grateful that the State Government is supporting us here with support from IN4climate.NRW. With Air Liquide for the hydrogen supply and the BFI as the scientific companion of the project, we have just the right partners at our side.”

Hydrogen: The key to a climate-friendly future

Hydrogen is a key driver for achieving climate ambitions because it does not cause climatedamaging emissions at the site. It can be stored and transported in liquid or gaseous form with a high energy density and offers so many possible applications. Because of its versatility, hydrogen plays a key role in the transition to a clean, low-carbon energy system. In steel production, hydrogen can be used as an emission-free reducing agent for iron ore. Air Liquide, project partner for the hydrogen project at thyssenkrupp Steel, which is now about to commence, has expertise in the entire hydrogen value chain, from production through storage to the development of end user applications. Gilles Le Van, Chief Executive Officer of Air Liquide Germany, said: “Here in Duisburg, a major chapter in industrial development is opening up: the gradual and sustainable de-carbonization of steel production. We are very pleased to be involved in this project - first in the trial run and later on a larger scale. Our long-time customer and partner thyssenkrupp Steel has repeatedly demonstrated how an innovative industry can be successfully combined with competitiveness and climate protection.”

About thyssenkrupp Steel

thyssenkrupp Steel is one of the worlds's leading suppliers of carbon steel flat products. With around 27,000 employees, the company supplies high-quality steel products for innovative and demanding applications in a wide varety of industries. Customer-specific material solutions and services around steel complete the range of services. With a production volume of approximately 12 million tons of crude steel annually, thyssenkrupp Steel is the largest flat steel producer in Germany.

https://www.thyssenkrupp-steel.com/en/

About Air Liquide

Air Liquide is a global leader in gases, technologies and services for industry and healthcare, with operations in 80 countries and around 66,000 employees. In 2018, it generated sales of approximately €21 billion. The company supplies three quarters of the industrial companies in the DAX and thus forms an important pillar of the German economy. Air Liquide Deutschland is based in North Rhine Westphalia and is active in industry associations such as the German Chemical Industry Association (VCI).

About In4climate

With the initiative “IN4climate.NRW”, the state government is supporting the necessary transformation processes in industry. Experts from business, science and administration are currently working on strategies and solutions for how the industry can maintain its competitiveness, generate additional growth and contribute to achieving the Paris climate protection goals.

About BFI

For 50 years now, BFI has been supporting the steel industry with solutions for current and future challenges as a non-profit research institute at the Association of German Steel Manufacturers (VDEh). It sees itself as a research partner, which, thanks to its specialist expertise and many years of experience, puts the important ability to connect knowledge into business practice. New topics of interest, such as energy efficiency, process optimization, measurement technology and industry 4.0, form the focus of the research.