Trade press, 2013-11-05, 02:44 pm

PowerCore SunCruiser team on the winners’ podium

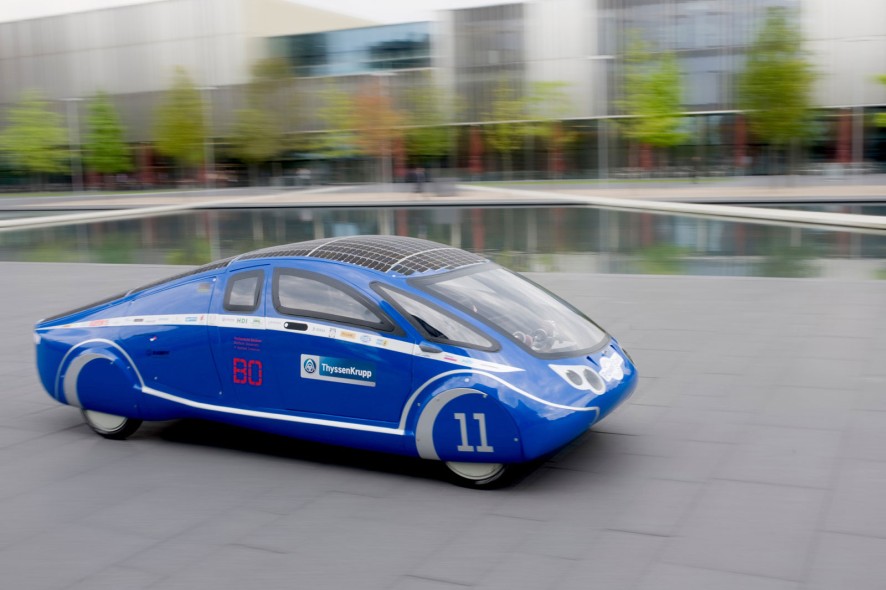

Solar car takes second place in World Solar Challenge in Australia

The SunCruiser team from Bochum University had every reason to celebrate at the Awards Night in Adelaide in mid-October: The PowerCore SunCruiser – a high-tech solar-powered vehicle developed jointly by Bochum University and ThyssenKrupp – took second place in the world’s toughest solar car rally, the World Solar Challenge in Australia. At this year’s Blechexpo in Stuttgart from November 5-8, ThyssenKrupp Steel Europe will demonstrate with the PowerCore SunCruiser that steel also holds great potential for use in electric vehicles (hall 5, booth 5307).

3,000 kilometers without any problems

The vehicle lined up in a new Cruiser class and had to fend off competition from nine other solar cars on the 3,000 kilometer course. “Even though we had to cede first place to the Dutch team, it was a great success,” says Stefan Spychalski, who has overseen the solar car project at Bochum University for over ten years and was also present in Australia. “The team is extremely proud of the way our roadworthy solar car performed so reliably on Stuart Highway, reaching top speeds of 100 kilometers per hour. Coming second is a great result – a German team has never made it into the top three before.” The PowerCore SunCruiser’s final placing was not only decided by the time it took to cover the 3,000 kilometers from Darwin to Adelaide. A formula was also used to take into account man-kilometers, i.e. the number of people traveling in the car times distance covered. Design and everyday practicality were also factored in. “The Cruiser class has introduced a new dimension to the solar car scene,” says Marco Tietz, head of non-oriented electrical steel applications at ThyssenKrupp Steel Europe, who oversaw the collaboration with Bochum University.

Motor uses electrical steel for the first time

ThyssenKrupp has supported the project from the outset. For the first time, the motor – which can be installed in the front or rear wheels of the vehicle – was made using electrical steel from ThyssenKrupp Steel Europe (Bochum site) and its subsidiary ThyssenKrupp Electrical Steel (Gelsenkirchen site). The material is a special soft magnetic steel used mainly in motors for efficient power transmission. It helps make very efficient use of the sun’s energy collected by the solar cells on the roof, with minimal core losses. The natural energy flows directly into the motor or in strong sunshine to the battery, where it is stored for use in dull weather.

Anyone interested can learn more about the diverse products and services of ThyssenKrupp Steel Europe at the Blechexpo exhibition taking place at Stuttgart Exhibition Center from November 5-8 (hall 5, booth 5307).

The Steel Europe business area is focused on the attractive market for premium carbon steel flat products, where it is one of the world's technology leaders. It employs around 27,800 people and generated sales of almost €11 billion in fiscal 2011/2012. Its capabilities range from intelligent material solutions and product-specific processing to comprehensive service. It serves a broad spectrum of steel-using sectors, including the automotive, shipbuilding, engineering, energy, construction, packaging and appliance industries.

Information for journalists

Image material with captions (under “Description”) can be downloaded here.