Videos

Climate neutral steel production becomes reality

Climate protection is part of our corporate DNA. With our strategy, climate-neutral steel production is gradually becoming a reality. Now we have taken another important step and are using hydrogen instead of blow-in coal in our ongoing blast furnace operations. You can see in our report what the experiment looked like and what this means for the transformation to climate-neutral steel production.

selectrify® – the initiative for high-tech steel solutions in electromobility

Everybody's talking about electric mobility. The automotive industry is facing a radical change. We as one of the leading steel producers in Europe support this change by providing the suitable materials. Because e-mobility is unthinkable without steel.

ZM Ecoprotect® for the best outer skin

Dual-phase steels - the new variety

A product range with so many options – thyssenkrupp’s dual-phase steels can be used in many ways.

Many criteria must be met if a company wants to be successful in the automotive industry, such as being environmentally friendly, conserving raw materials, and keeping costs low at all times. Yet demands placed on safety and comfort are rising. But it is not difficult to design lighter vehicles and make them affordable, as the Product Management area in thyssenkrupp’s Steel division has oriented its product range for cold-rolled dual-phase steels more toward the needs of customers and added new grades.

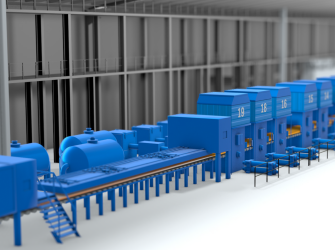

Hohenlimburg precision strip

The Precision Steel business unit employs a state-of-theart rolling mill to produce hot-rolled strip with special material properties and extremely close manufacturing tolerances. All processes are fully automated and are controlled and monitored by digital systems.